PRODUCTION FACILITIES.

CNC MACHINING.

CNC-MACHINING.GREAT PRECISION.

MANY POSSIBILITIES.

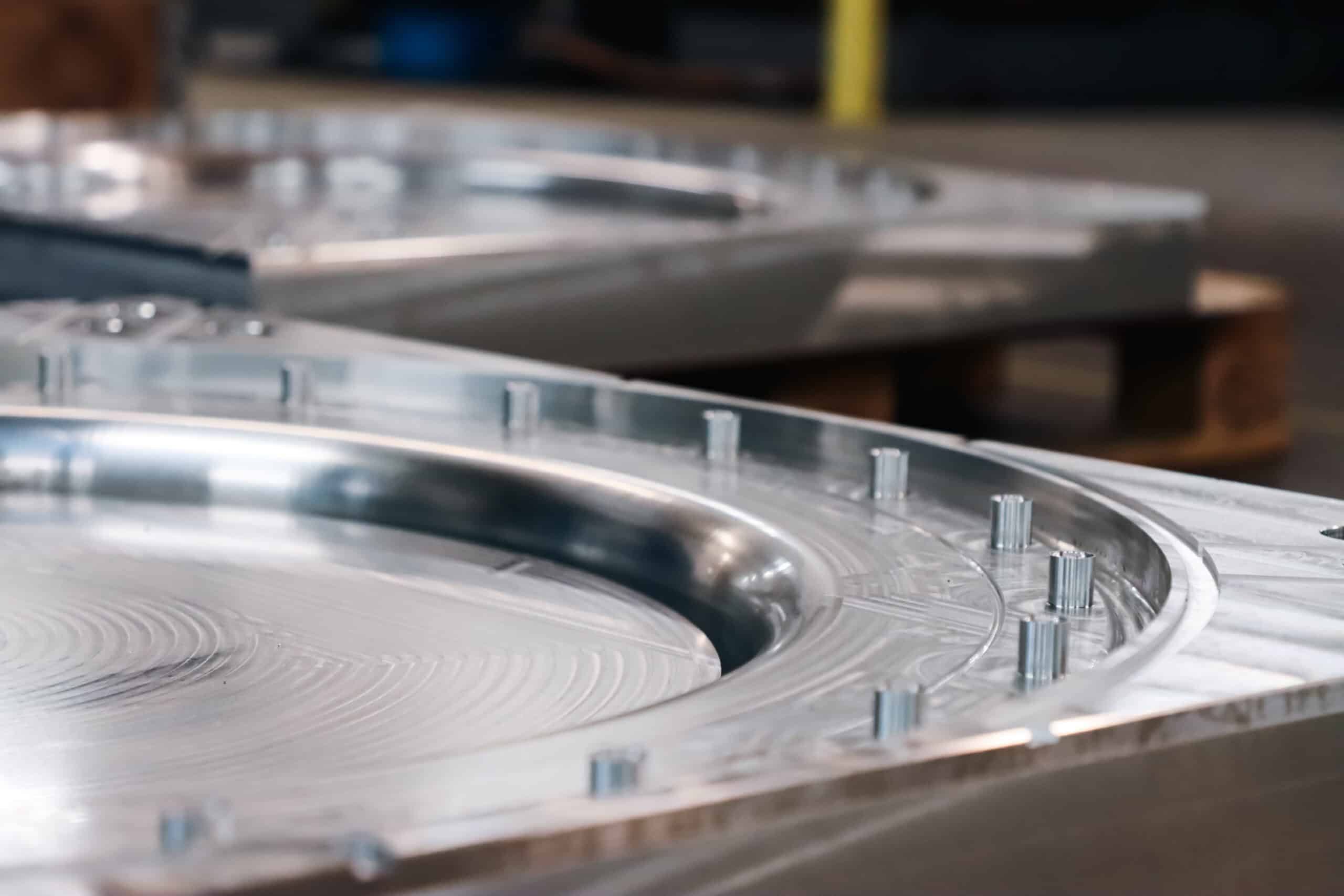

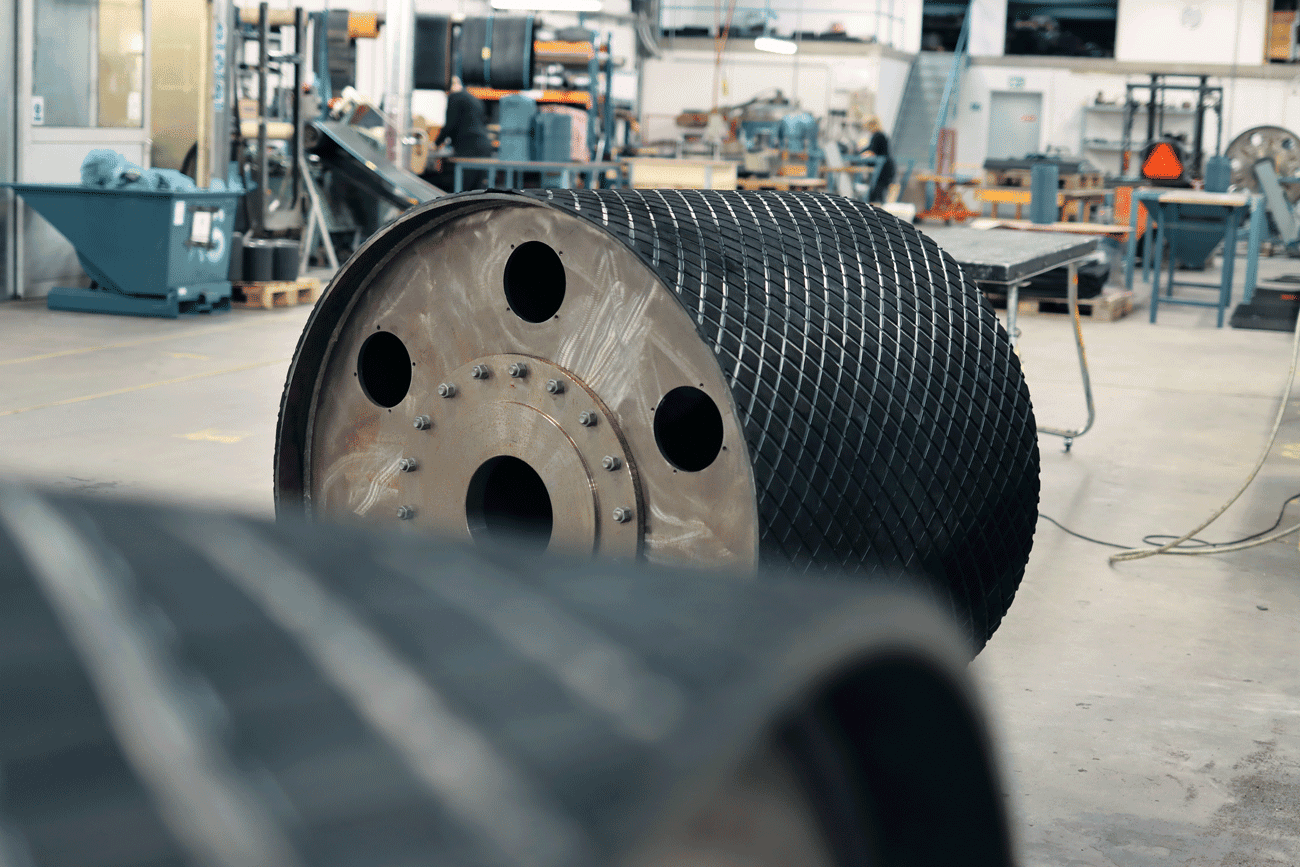

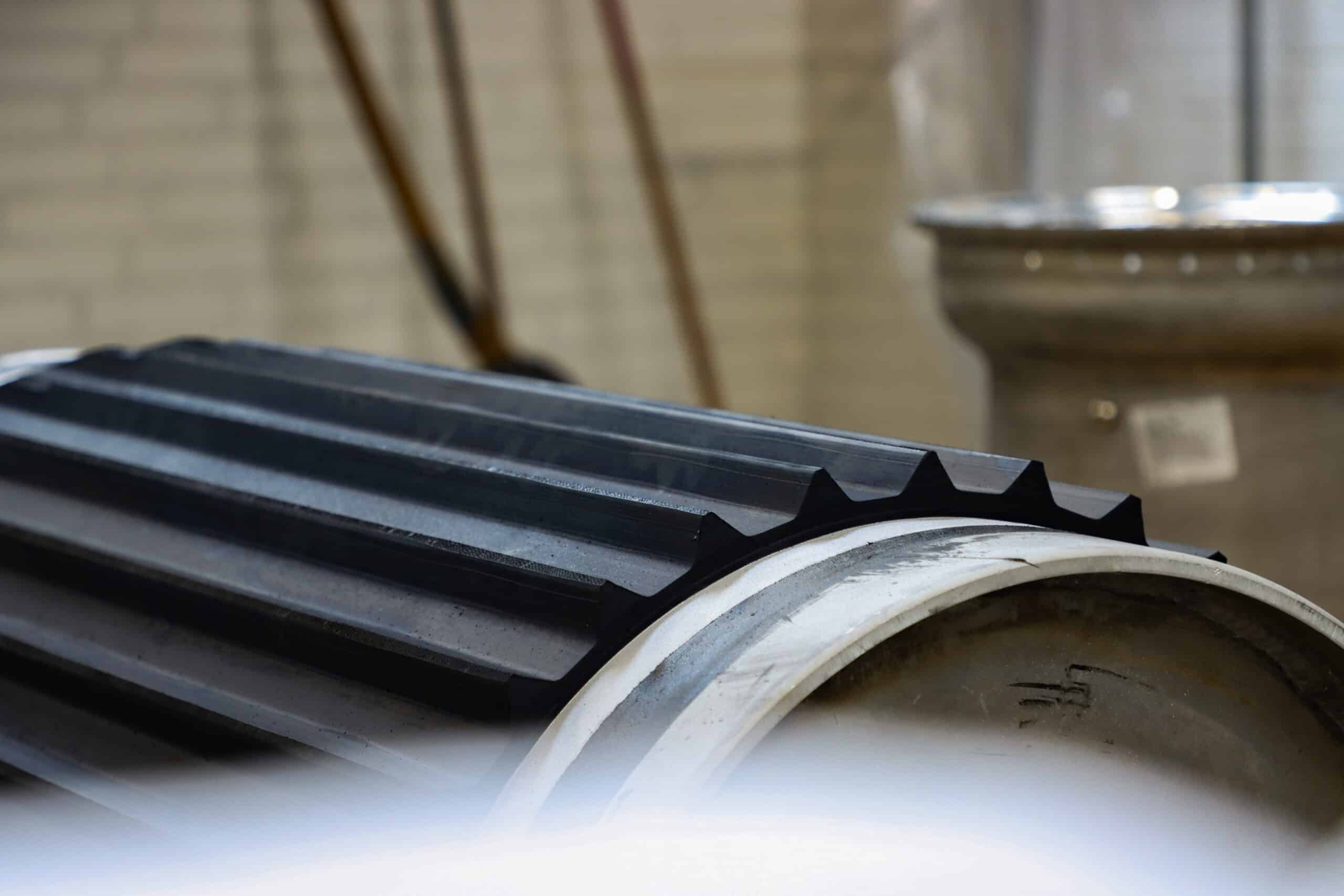

As one of the industry’s largest and most versatile in-house manufacturers of rubber, plastic or foam solutions, our production facilities are crucial. We have a large and modern production department dedicated exclusively to CNC machining in rubber, plastic and foam. Our capabilities are many and unique in our industry. For example, we use For example, we use CNC turning for our rubber rollers and CNC milling for the production of molds and tools.

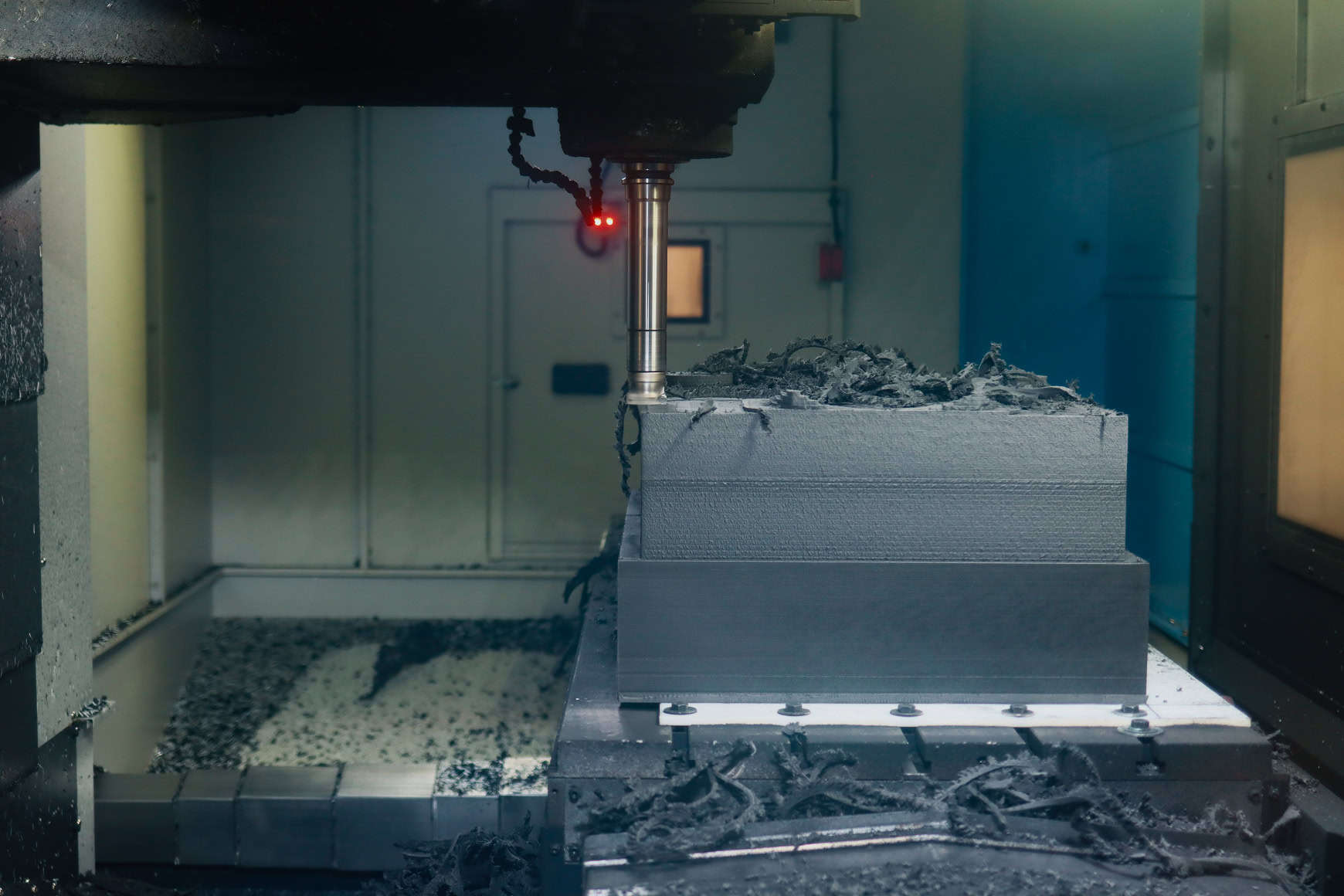

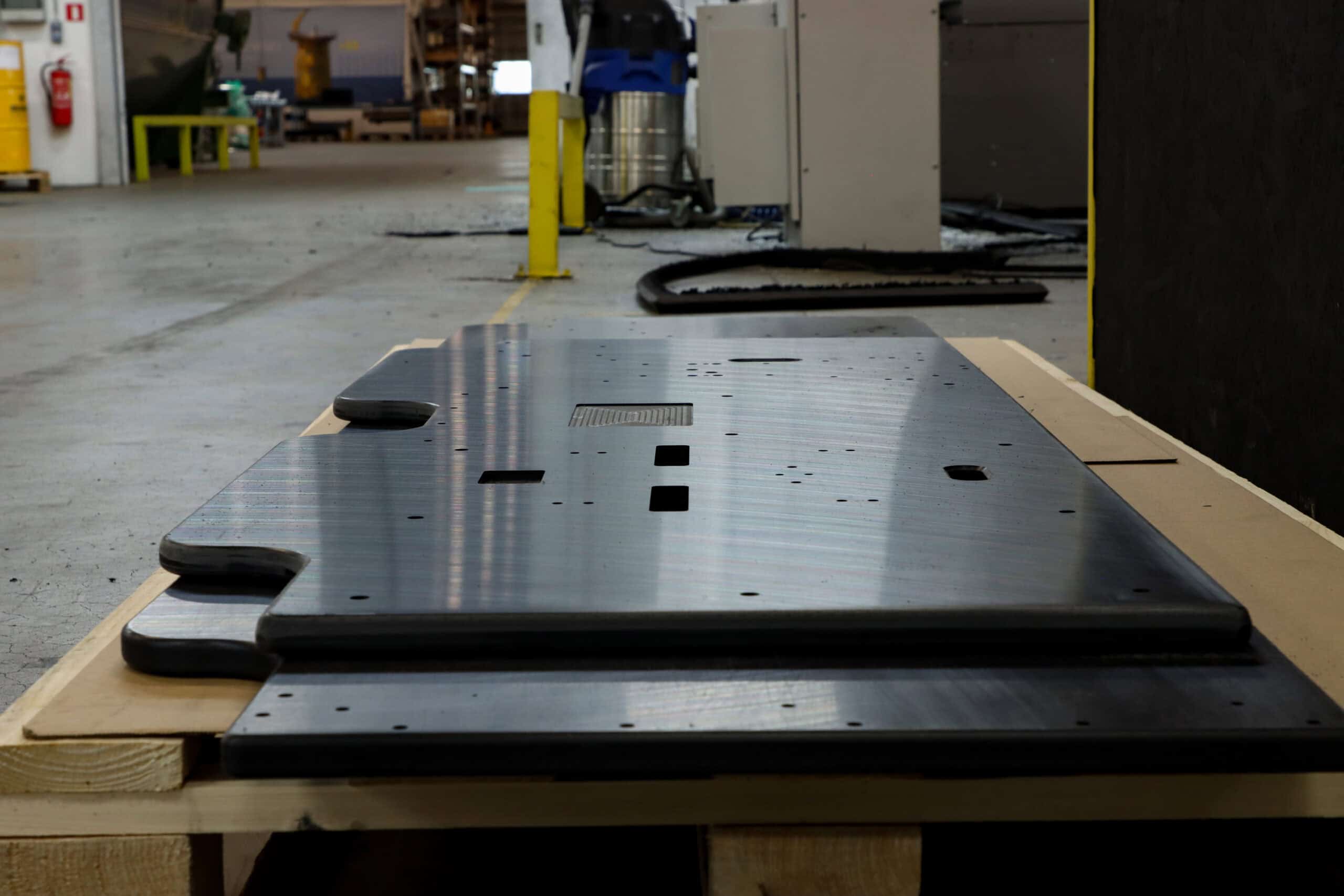

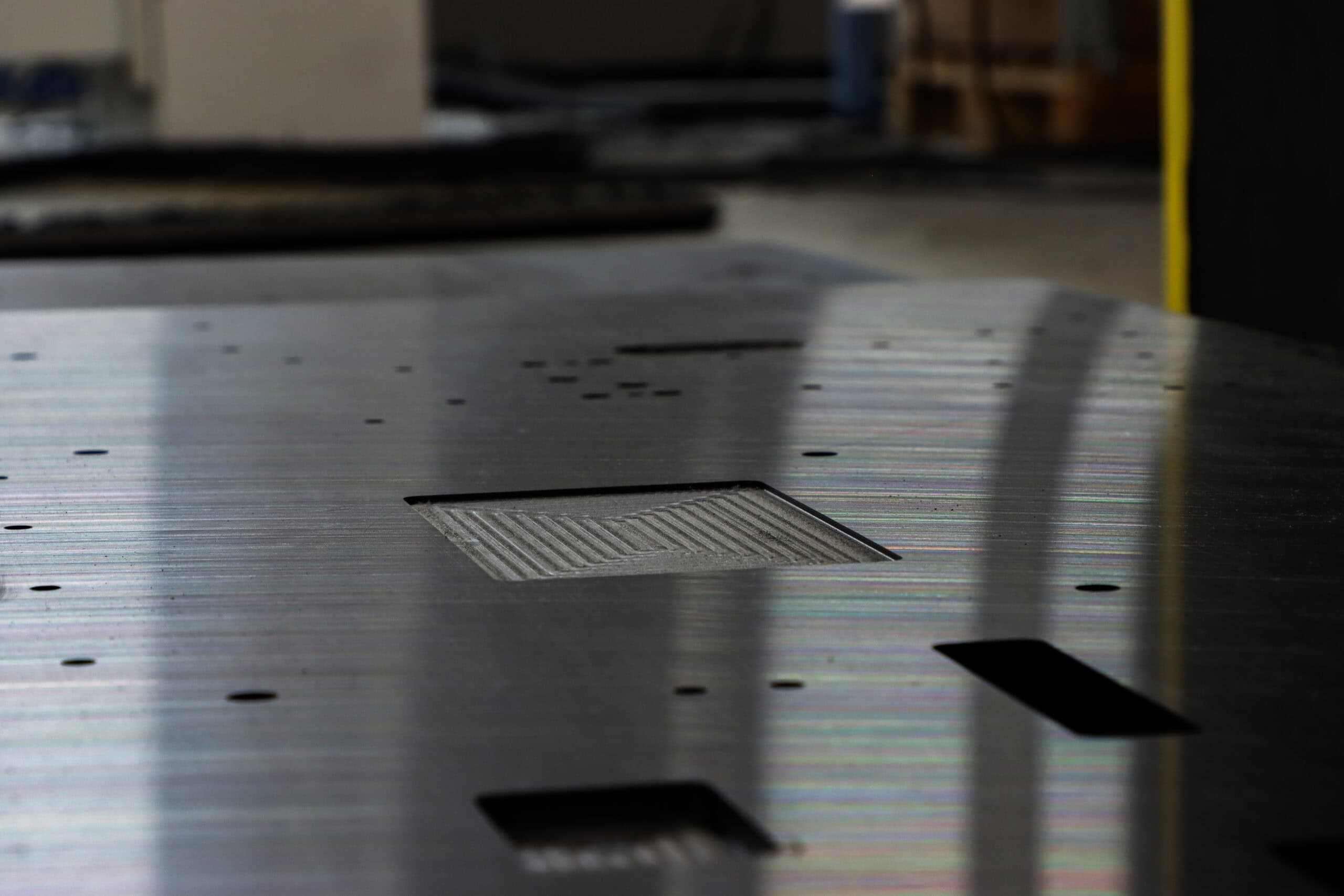

CNC-MILLING.

With our 3 modern CNC milling machines, we manufacture and process everything from technical plastic and foam parts to molds and tools.

Our CNC milling machines have a working range of up to 3,100mm in the x-axis and 762mm in the y-axis.

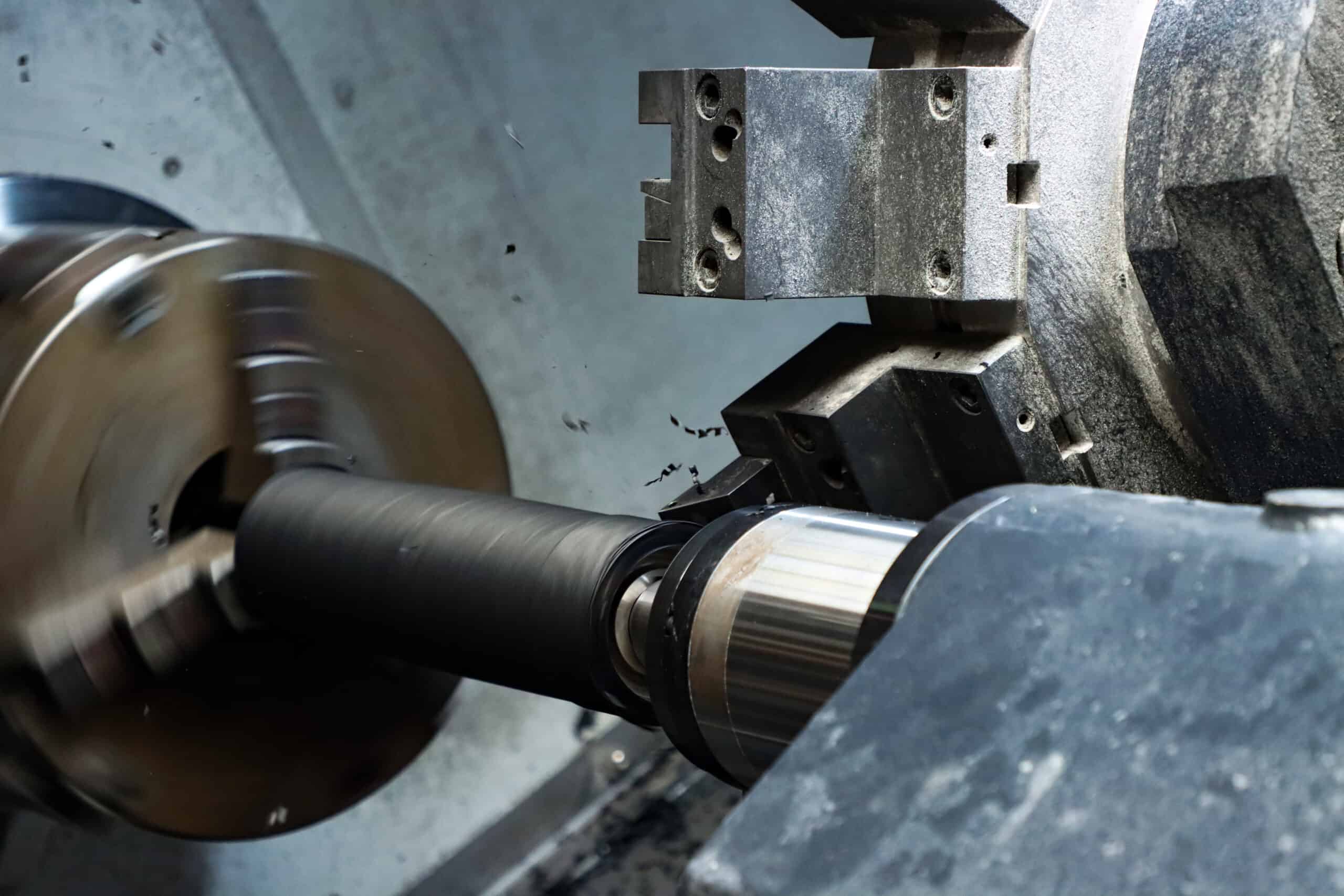

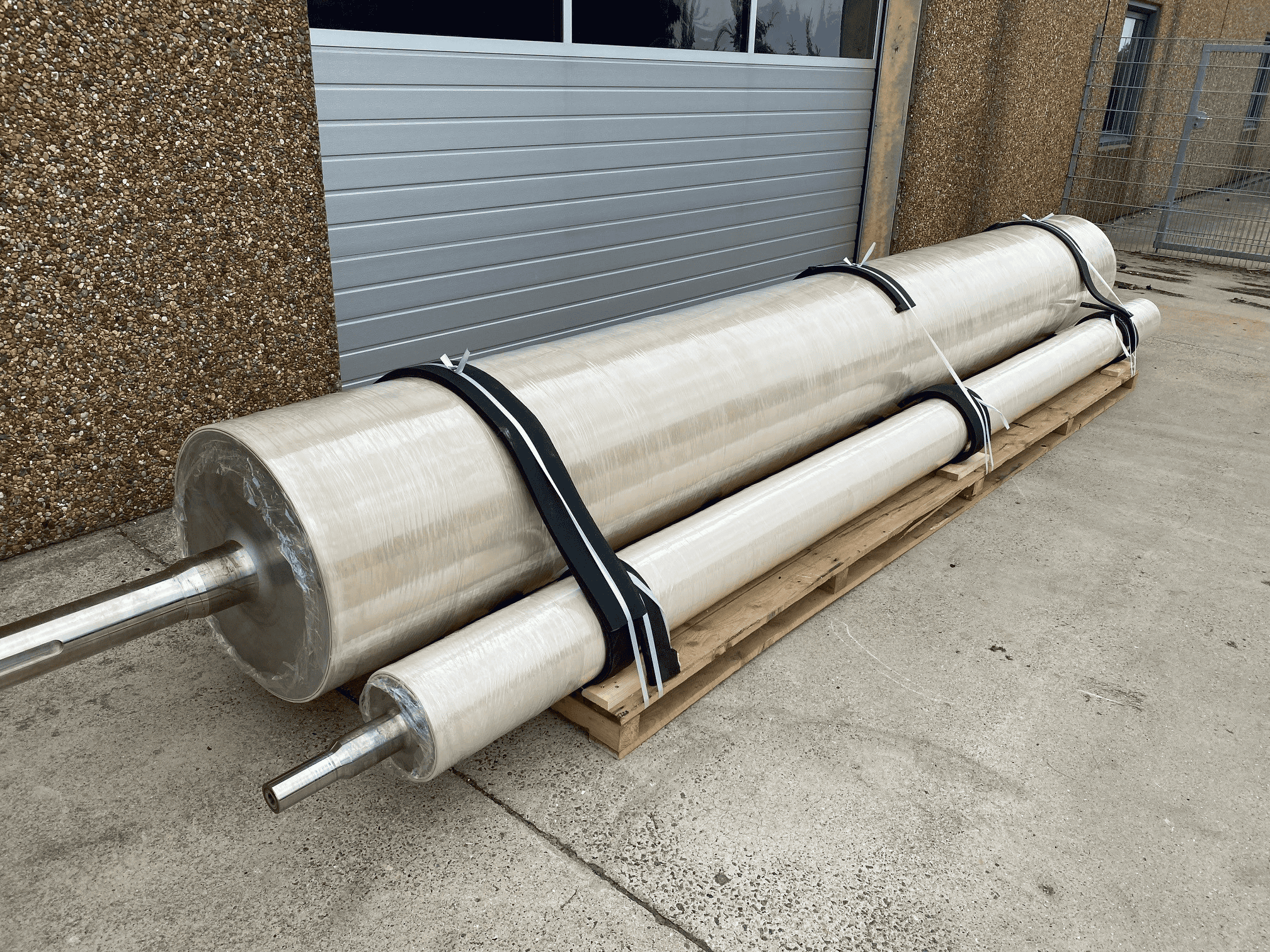

CNC-TURNING.

With our 5 versatile turning centers, we turn and machine everything from small parts in technical plastics to large rubber rollers. Our turning centers have a working range up to Ø1000 mm and a turning length of 5000 mm. For example, we use CNC turning to finish our rubber rollers, drums, plastic parts and rubber solutions for offshore wind turbine foundations.

.

PLENTY OF OPTIONS. HERE ARE A FRACTION OF THEM.

THERE ARE MANY GOOD REASONS TO CHOOSE US. HERE ARE 3 OF THEM.

1.

FAST PRODUCTION 24/7. EXPRESS DELIVERY.

With our 18,000 m² in-house production facility in Lemvig, we can produce and work with everything related to technical rubber, foam, and plastic, offering a delivery time that few in the industry can match. If your project is urgent, we are willing to work overnight to have your products ready as quickly as possible.

2.

HAVE PEACE OF MIND WITH APPROVED PRODUCTS.

We use well-documented, high-quality materials and rubber compounds that ensure our solutions meet the necessary standards and qualities for use in industries such as food, healthcare, or Swan-labeled construction.

3.

OUTSTANDING SERVICE THAT MAKES YOUR WORKDAY EASIER.

We are a full-service manufacturing company dedicated to making everyday life easier for our customers through high service levels, great flexibility, and quick response times. For example, avoid the hassle of sourcing steel components for your rubber solution, or receive your products pre-packaged in your own packaging.

LET’S GO IN-DEPTH AND FIND THE PERFECT SOLUTION.

Do you have a challenge or an idea for a solution in rubber, plastic, or foam? Or are you interested in learning more about our solutions and expertise? Please reach out to one of our specialists. Let’s go into detail so we can find the perfect solution that meets your needs.