CASE.

DURABLE RUBBER WEAR PLATES FOR MIDTJYDSK BETON A/S.

SAMARBEJDE.

SLIDGUMMI OPTIMERER DRIFTEN FOR MIDTJYDSK BETON A/S.

We have supplied our unique RG wear rubber to Midtjydsk Betonwhich has been manufacturing precast concrete elements for office, industrial and residential buildings for more than 60 years.

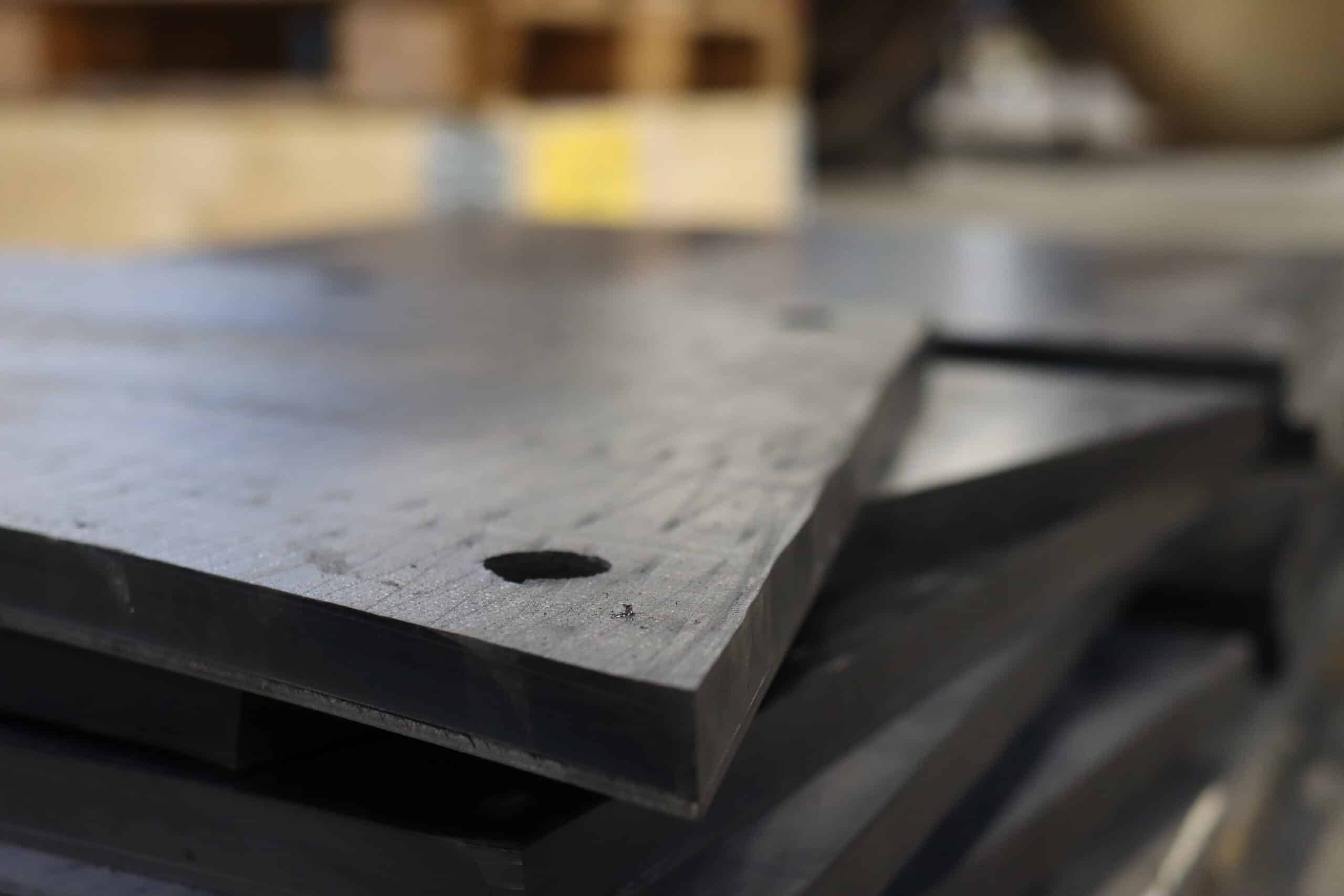

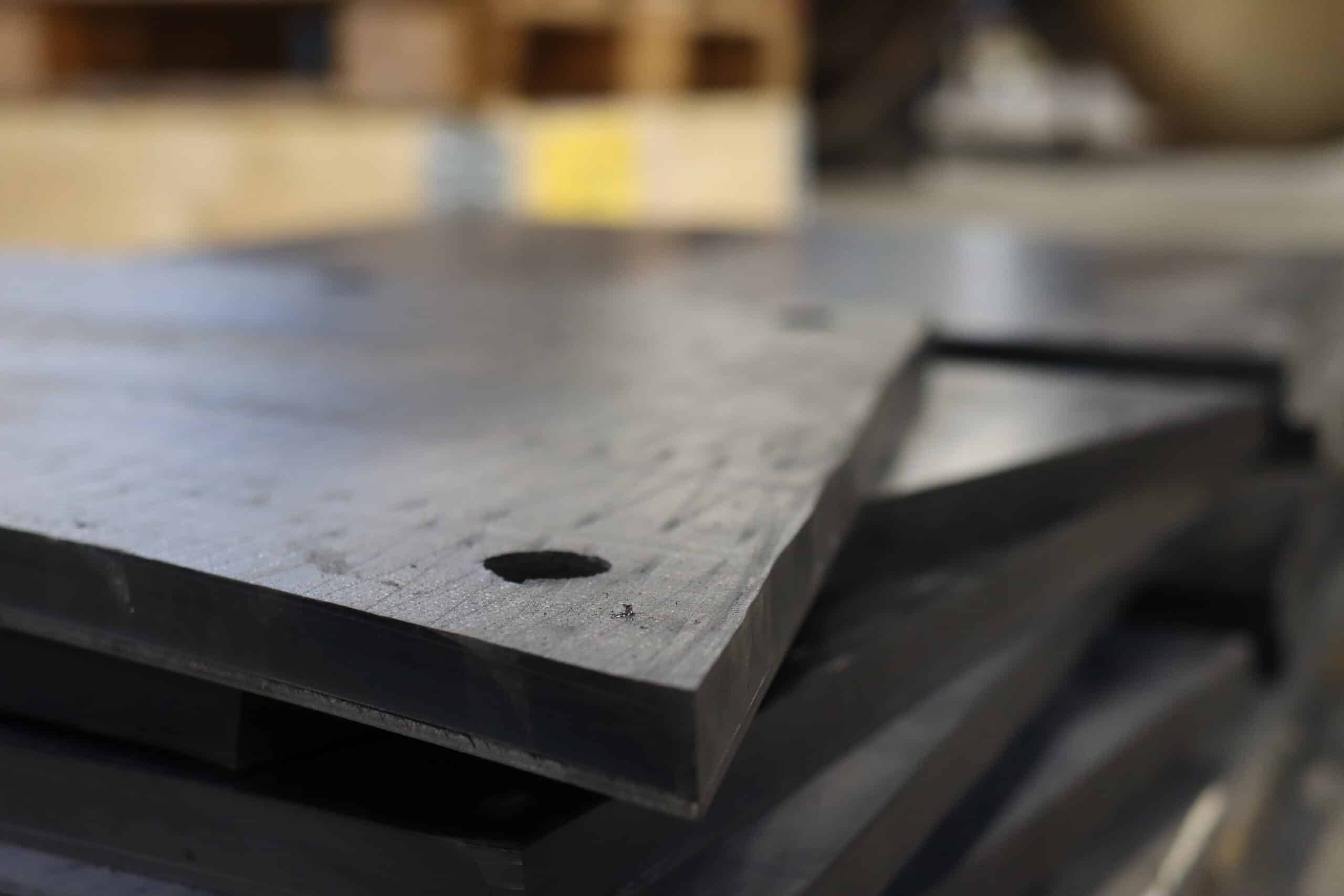

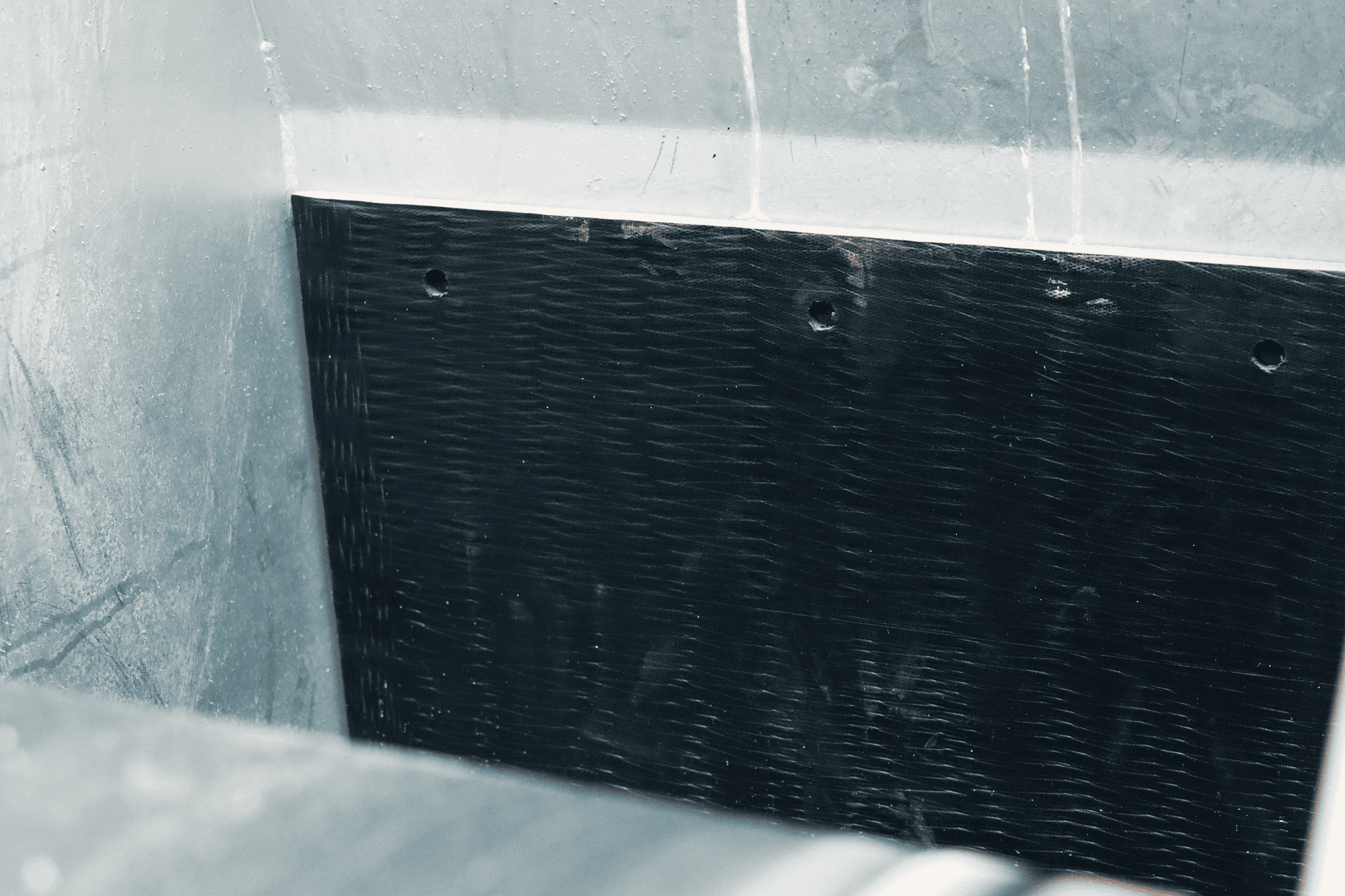

To protect their production facilities, wear plates are installed to protect against sand, stones and gravel used in the production of the finished concrete. The wear plates are located at the belt from the filling pit, the belt in the knee tower, the distributor belt, the silo top and the transition between the aggregate weigher and the mixer.

Before Midtjydsk Beton started using our RG wear rubber on their wear plates, they had to replace the wear plates after 8 months because the raw material had worn through the rubber and steel plate.

With our unique RG wear rubber solution on their wear plates, they have managed to keep production running for 3 years without any replacement.

FEWER PRODUCTION STOPS.

5

MBE saves 5 production stops by using our RG wear rubber on their wear plates.

INCREASED EFFICIENCY.

350%

With our RG wear rubber, we have extended the service life of MBE wear plates from 8 months to a minimum of 3 years.

FEWER MAN-HOURS.

48

MBE saves 48 man-hours over a period of 3 years, which our RG wear rubber extends the service life of the wear plates.

STATEMENT.

“We have to admit that RG ROM GUMMI lives up to their word and delivers a rubber solution that really outperforms the wear plates we previously got from other suppliers”

We were a bit skeptical when RG ROM GUMMI claimed that their rubber solution for wear plates is more wear-resistant than other rubber solutions on the market. We have a number of wear plates in different places in our plant and therefore gave their hot vulcanized rubber solution a chance. We have to admit that RG ROM GUMMI lives up to their word and delivers a rubber solution that really outperforms the wear plates we previously received from other suppliers.

Normally we changed our wear plates after 8 months of operation because the material had worn through the rubber. Now we have been using the rubber from RG ROM GUMMI on our wear plates, and even after 9 months of operation, there was not the slightest sign of wear. We expect their rubber to easily achieve a lifetime of 3 years, corresponding to approx. 90,000 tons of raw material.

Thanks to their durable rubber solution, we don’t have to change the plates every 8 months and put the entire production on hold. In addition, we save on labor and resources for installing new wear plates, which over a 3-year period would amount to 48 man-hours, plus the cost of new plates.

I would therefore definitely recommend RG ROM GUMMI’s solution to other concrete or cement plants, as I’m sure it will also make a huge difference to their wear plates, as they have to ours.

In the past, our raw material has simply worn holes in the rubber and steel plate, resulting in stones and sand flying all over the place. Therefore, we always checked the plates before 8 months had passed to make sure it doesn’t happen again.

Christian F. Nielsen

Concrete Manager

MBE

kontakt os.

LAD OS GÅ I DYBDEN OG FINDE DEN HELT RIGTIGE LØSNING.

Sidder I med en udfordring eller ide til en løsning i gummi, plast eller skum? Eller er I interesseret i at høre mere om vores løsninger og kompetencer, skal I endelige tage fat i en af vores specialister. Lad os gå i detaljer så vi sammen kan finde den helt rigtige løsning, som passer til jeres behov.

Error: Contact form not found.