case.

PROTECTION OF PIPE BENDING KROGHS A/S.

samarbejde.

FORLÆNGET DRIFTSTID. FRA 4 MÅNEDER TIL 3 ÅR.

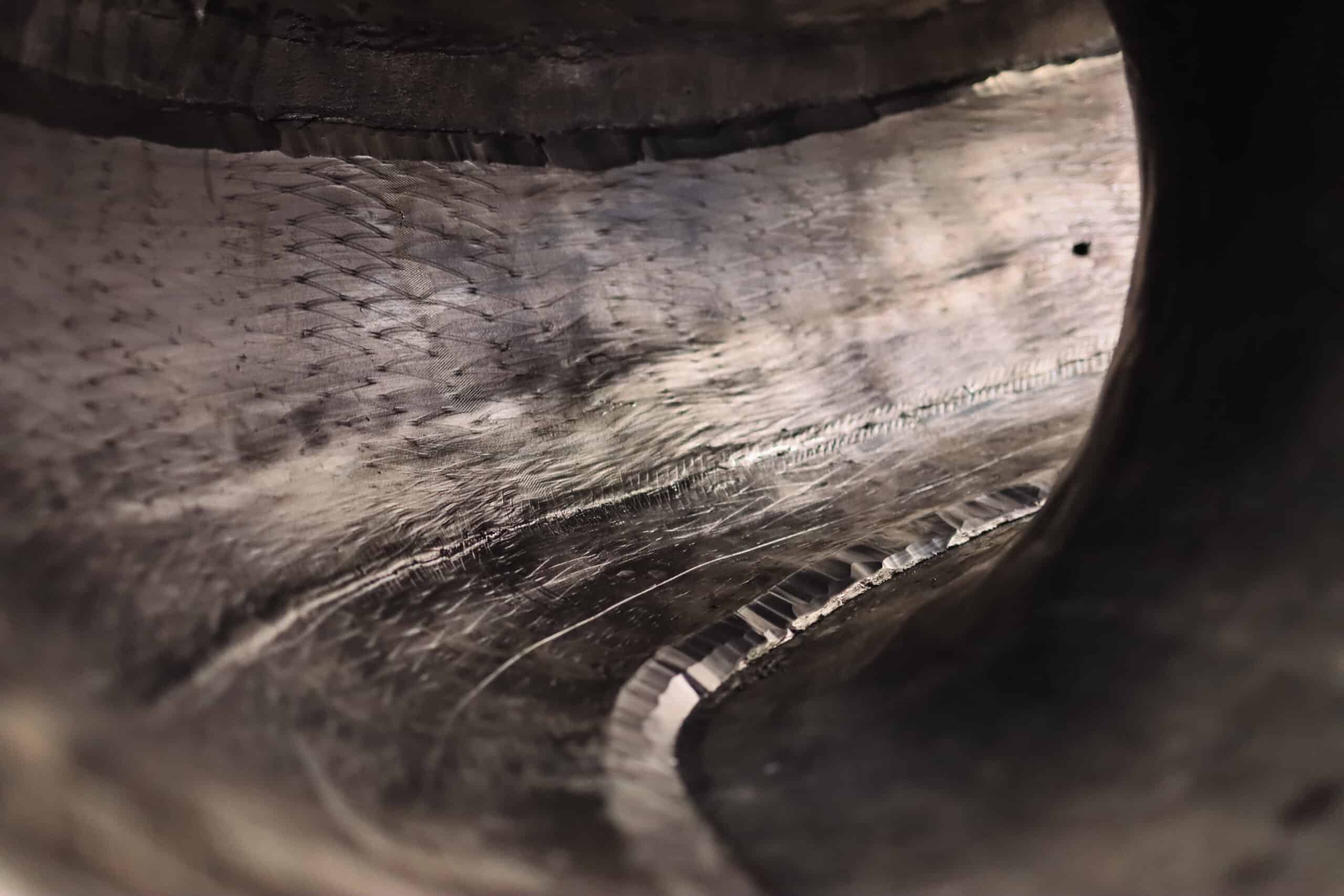

We have supplied our unique hot vulcanized RG wear rubber to Kroghs A/S, which extracts sand and rock from the seabed for use in concrete and cement factories. Kroghs A/S has many components that are exposed to enormous wear, such as this pipe bend.

Previously, Kroghs A/S used heavy steel as internal protection, but still had to replace the pipe bend every 4 months due to the large amount of sand, stones and sea water that wore away the coating.

With our durable rubber solution, it has been tested and proven that the pipe bend can now last for a minimum of 2 years, which is equivalent to 1,728,000 m³ of mixed sand, rock and water.

INCREASED DRIVE TIME.

506%

With our RG wear rubber, we have extended the service life of Krogh’s pipe bending from 4 months to a minimum of 2 years.

FEWER REPLACEMENTS.

5

Kroghs A/S saves 5 replacements of their pipe bend over a period of 2 years by using our RG wear rubber as internal protection.

STATEMENT.

u

“I would definitely recommend RG ROM GUMMIS solutions for wearing parts as it really makes

a difference in operation and lifetime”

With their rubber solution, RG Rom Gummi has extended the operating time of several of our pipe bends for our sand pumps.

I am very impressed with the durability and wear resistance their rubber solutions have shown. Thanks to their rubber solution, we can now use our pipe bends for 2-3 years, which is a huge difference compared to what we were used to before, which was only 4-5 months.

Steen M. Krogh

Director, Kroghs A/S

kontakt os.

LAD OS GÅ I DYBDEN OG FINDE DEN HELT RIGTIGE LØSNING.

Sidder I med en udfordring eller ide til en løsning i gummi, plast eller skum? Eller er I interesseret i at høre mere om vores løsninger og kompetencer, skal I endelige tage fat i en af vores specialister. Lad os gå i detaljer så vi sammen kan finde den helt rigtige løsning, som passer til jeres behov.

Error: Contact form not found.