PRODUCTION FACILITIES.

RUBBER MOLDING.

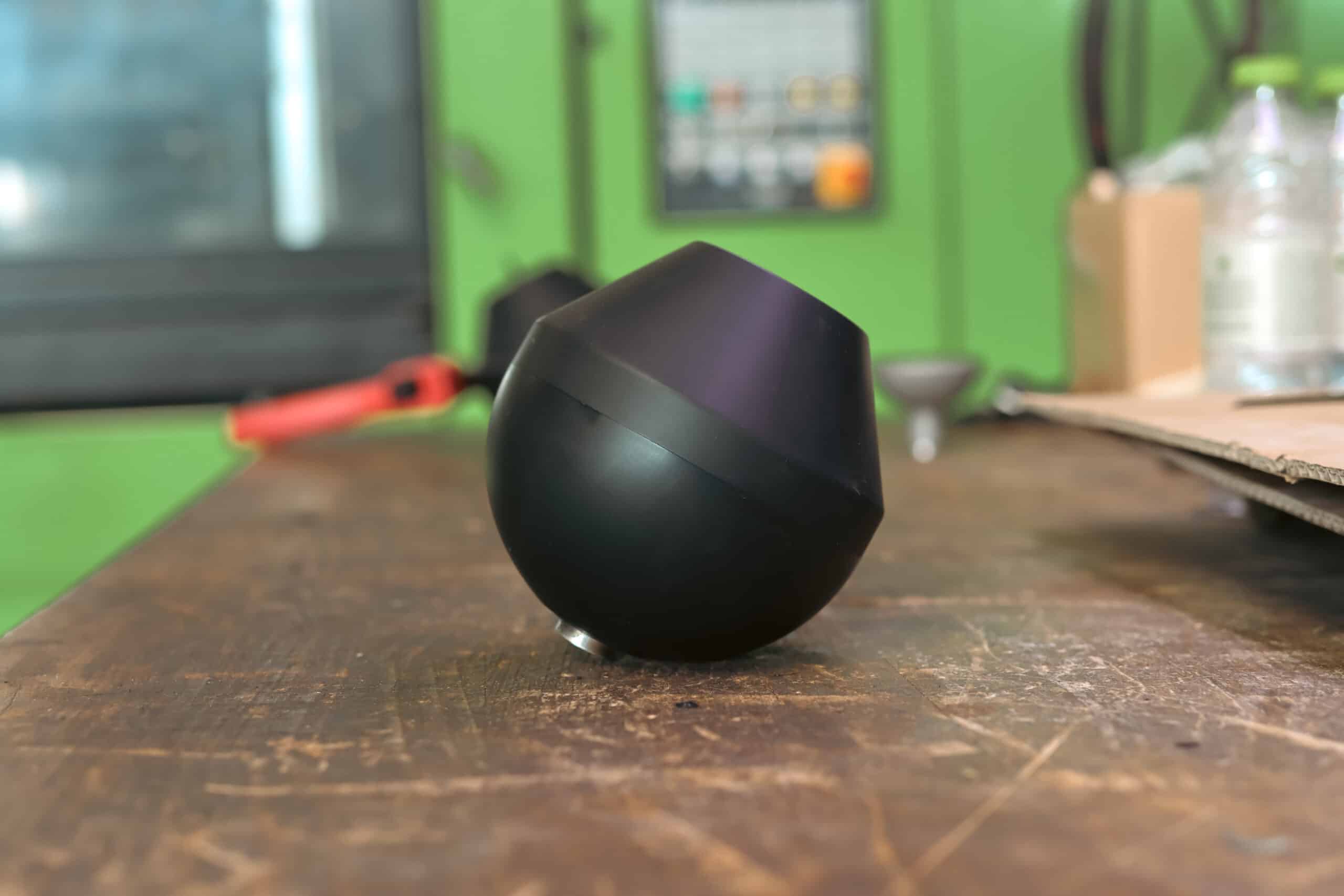

RUBBER MOLDING. ONE OF OUR MAJOR SPECIALTIES.

RG ROM GUMMI is one of Denmark’s largest in-house manufacturers of rubber molding and molded rubber solutions for all industries. Whether the molded rubber solution you need is a simple membrane or a highly complex valve, we specialize in manufacturing customer-specific solutions that meet high demands on properties, finish, complexity and rubber qualities.

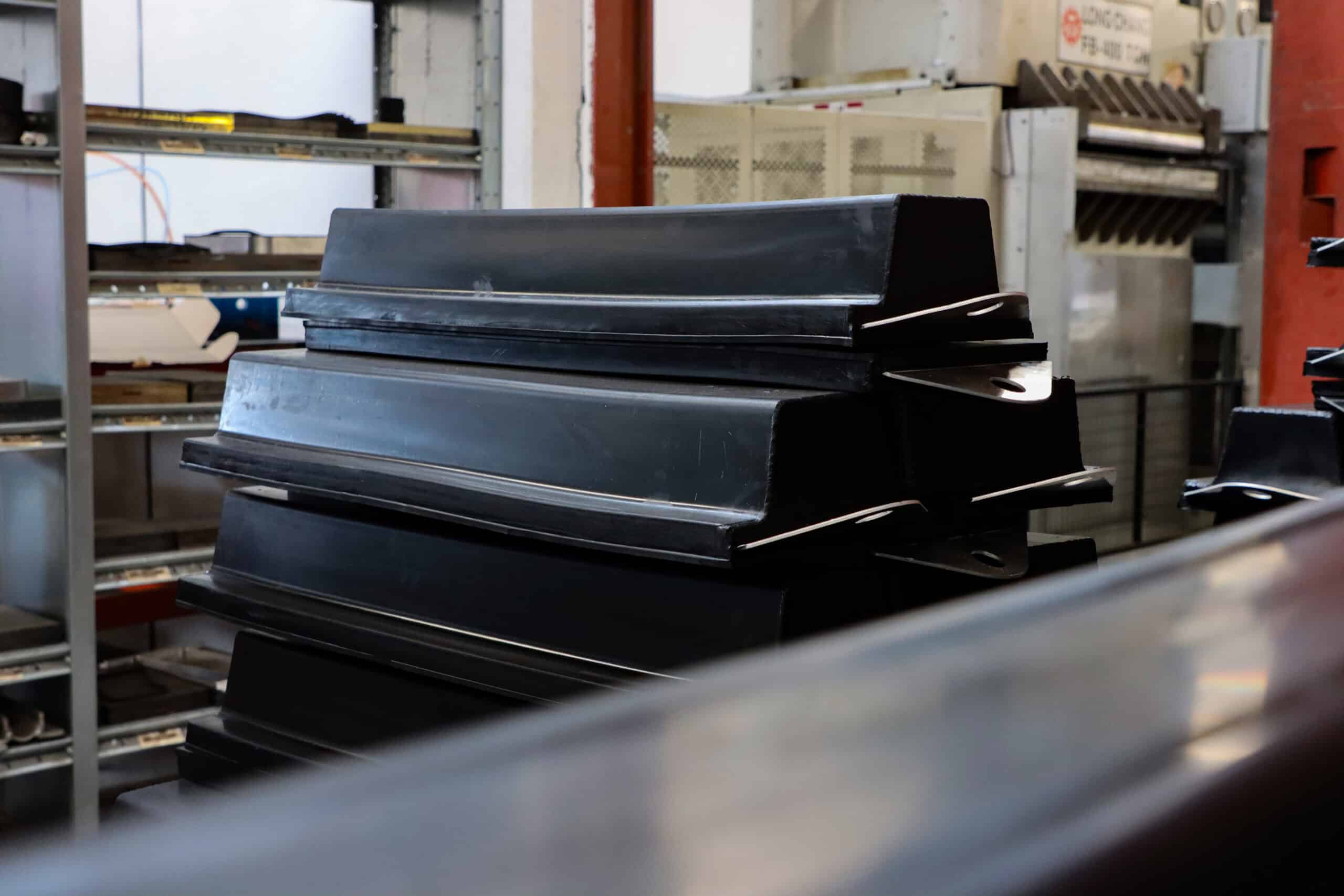

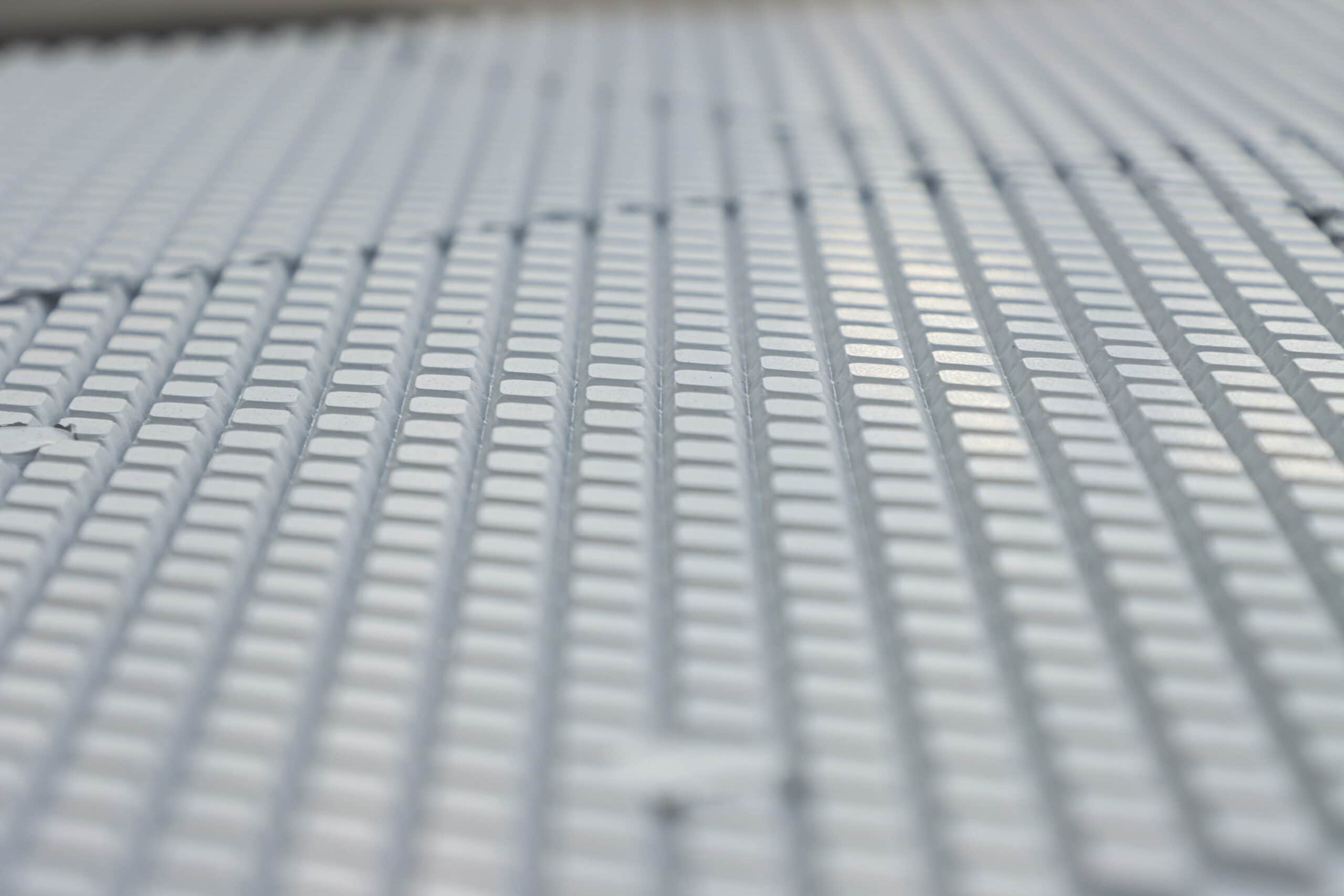

AUTOMATED MOLDING. PERFECT FOR LARGE SERIES PRODUCTION.

With our modern production facilities, we can automate casting and produce product batches of +10,000 pieces quickly and efficiently, without compromising on product consistency, quality or tolerances.

IN-HOUSE PRODUCTION. PREMIUM ITEMS.

We have been working with rubber molding since 1983, molding everything from large custom gaskets to micro-parts of 0.03g/piece. for applications in the food, healthcare and machinery industries, among others.

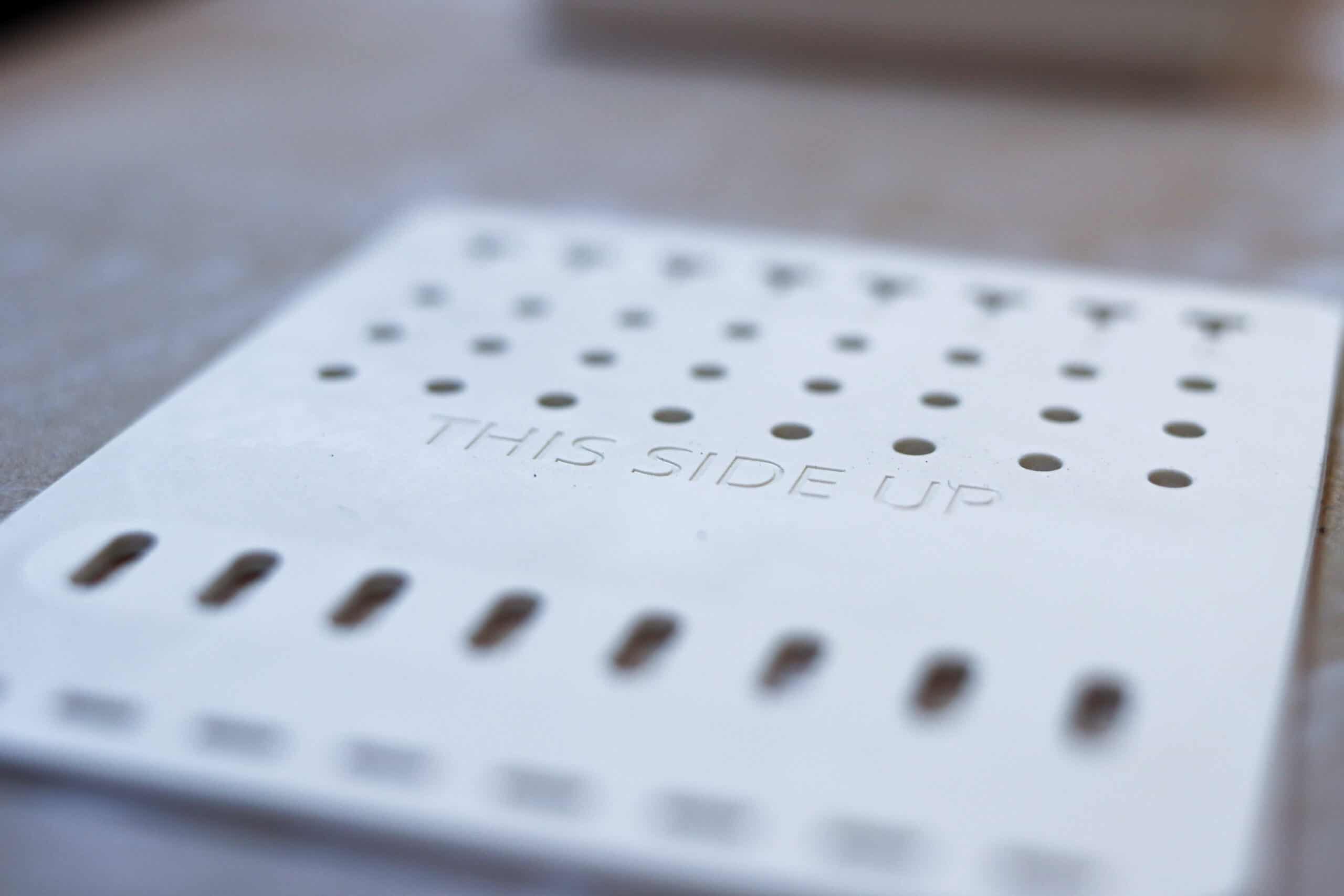

WISH FOR COLORS AND QUALITY? DON’T WORRY, WE’RE USED TO IT.

When we manufacture your molded rubber solution, the most important thing for us is that it meets your application, needs and specifications 100%. We can adjust a multitude of parameters to ensure they meet even the highest requirements for properties, finish, complexity, legislation, RAL colors and tolerances.

AVOID LONG WAITING TIMES FOR MOLDS.

For us, it is important that both the quality and delivery time of our molded rubber solutions are first-class.

That’s why we place high demands on the molds and tools we use, as they are crucial to the final result.

We have invested in a large and modern CNC machine shop where we can develop, manufacture and renovate molds ourselves.

This means that you quickly end up with a mould that is guaranteed to be 100% optimized and specified for your solution.

BLIV KUNDE HOS OS. GØR ARBEJDSDAGEN LETTERE.

With us, you don’t just get the right product. You also get a level of service and flexibility that is unique in the industry and makes your work easier. We are happy to handle some of the processes involved in your molded rubber solution such as

- Procurement of related components

- Procurement of private label packaging

- Packing in private-label packaging

- Sourcing of related components

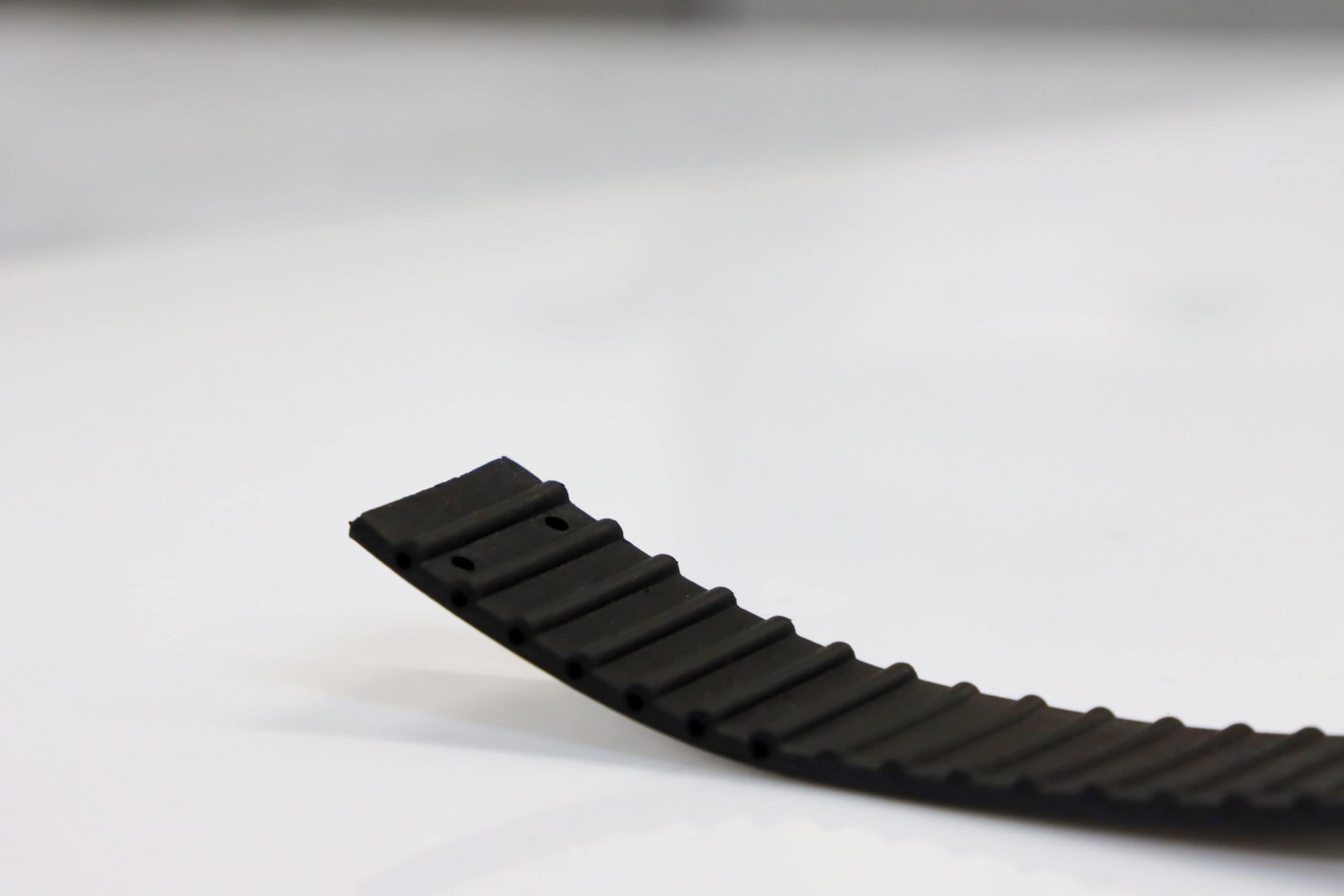

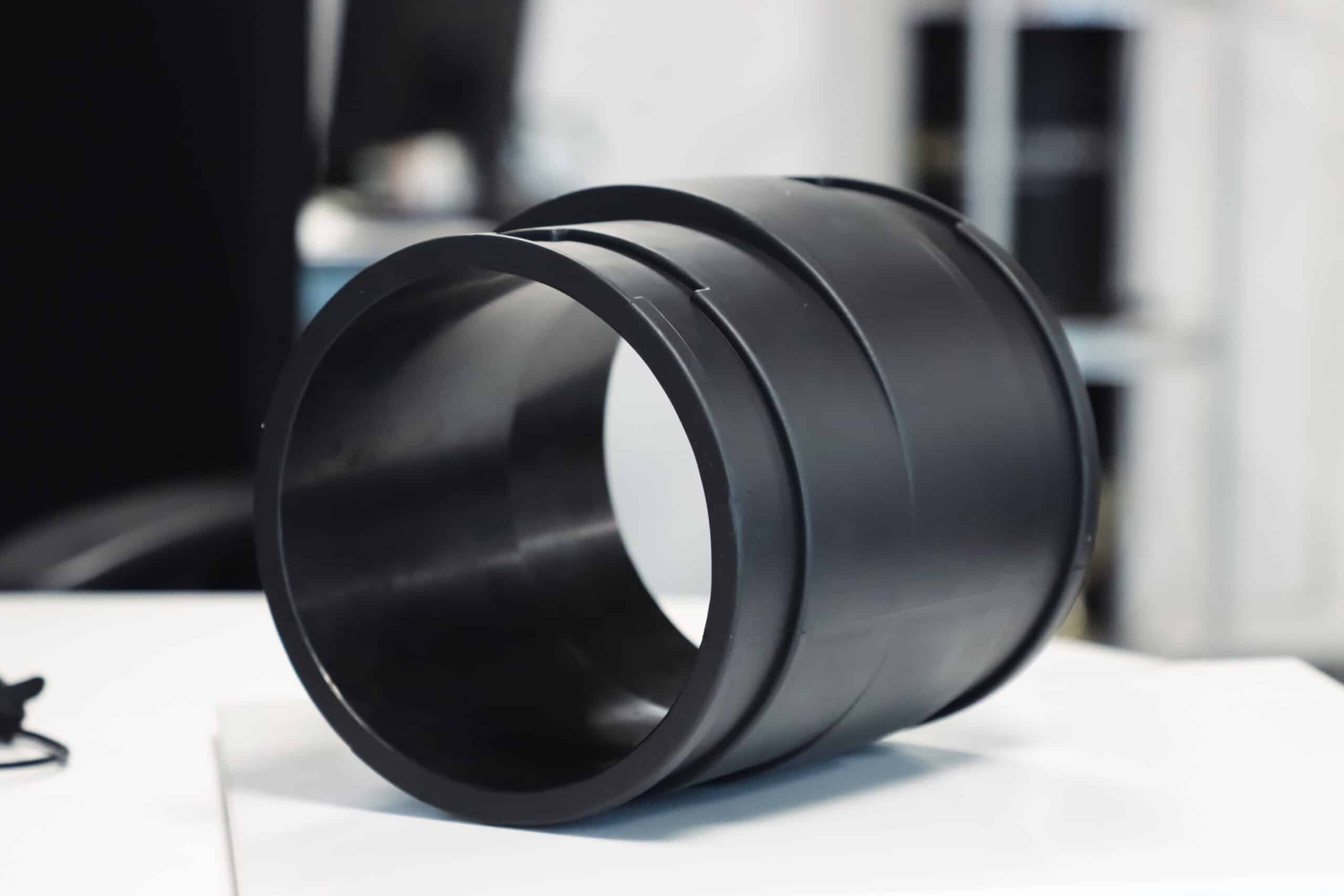

A MOLD METHOD ONLY FEW CAN REPLICATE.

We are one of the few manufacturers in the industry that can injection mold different rubber compounds directly onto components in either aluminum, metal, brass or steel. This unique molding method is both fast and ensures unparalleled adhesion between the rubber and the component, providing the absolute best durability and quality.

PLENTY OF OPTIONS. HERE ARE A FRACTION OF THEM.

THERE ARE MANY GOOD REASONS TO CHOOSE US. HERE ARE 3 OF THEM .

1.

FAST PRODUCTION 24/7. EXPRESS DELIVERY.

With our 18,000m² in-house production facility in Lemvig, we can produce and work with everything in technical rubber, foam and plastic, and offer a delivery time that few in the industry can match. If your project is urgent, we are happy to work at night so we can have your products ready the next morning.

2.

HAVE A CLEAR CONSCIENCE WITH APPROVED PRODUCTS.

We use well-documented and high-quality materials and rubber compounds that ensure our solutions meet the necessary standards and qualities for use in e.g. the food industry, health-care industry or Nordic Swan Ecolabeled buildings.

3.

EXCEPTIONAL SERVICE THAT MAKES YOUR WORKDAY EASIER.

With our 18,000m² in-house production facility in Lemvig, we can produce and work with everything in technical rubber, foam and plastic, and offer a delivery time that few in the industry can match. If your project is urgent, we are happy to work at night so we can have your products ready the next morning.

LET’S GO IN-DEPTH AND FIND THE PERFECT SOLUTION.

Do you have a challenge or an idea for a solution in rubber, plastic, or foam? Or are you interested in learning more about our solutions and expertise? Please reach out to one of our specialists. Let’s go into detail so we can find the perfect solution that meets your needs.