INDUSTRIES.

SOLUTIONS FOR WIND TURBINES AND FOUNDATIONS.

FROM THE BOTTOM UP

THE FOUNDATION.

TO

THE TOP OF THE WIND TURBINE.

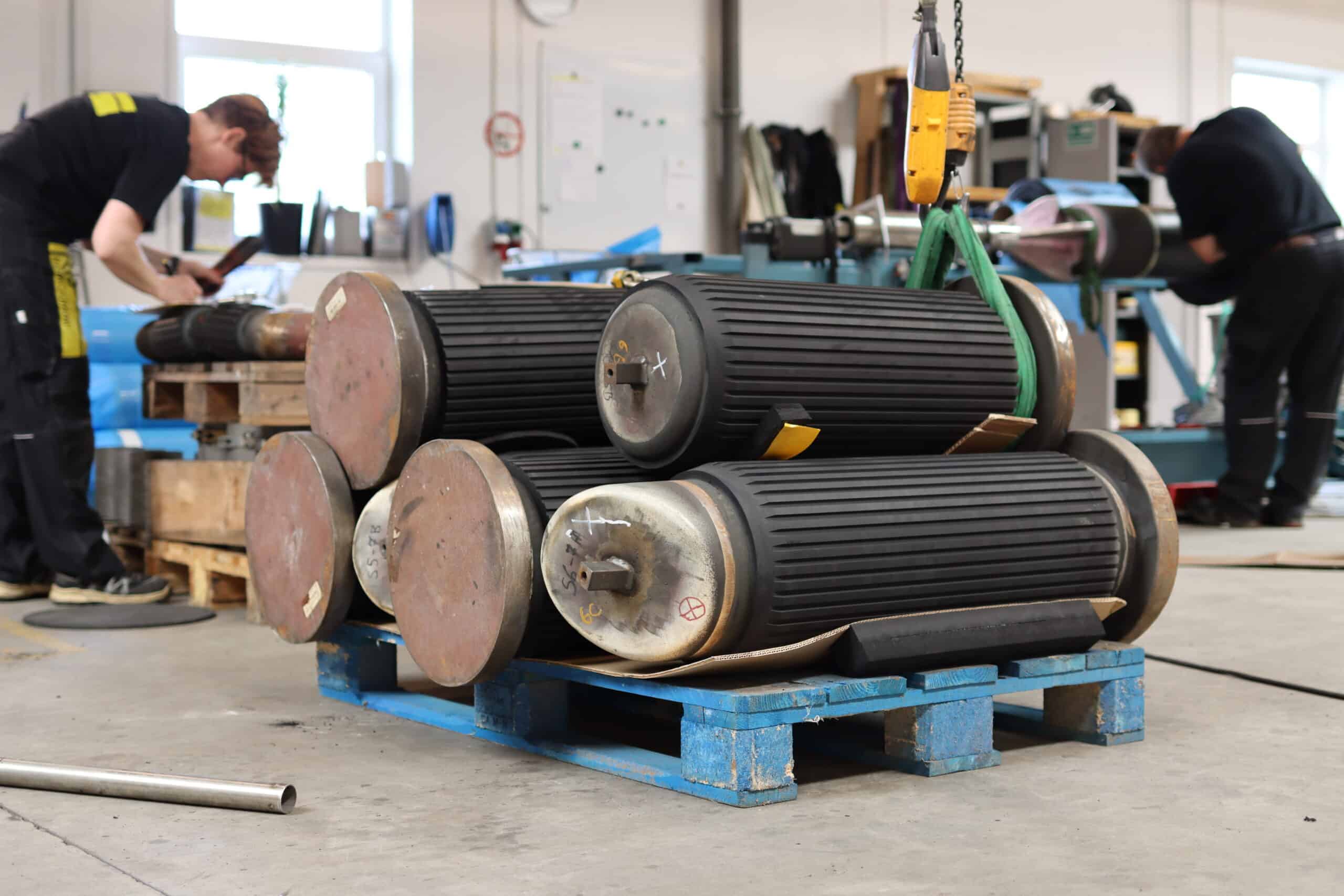

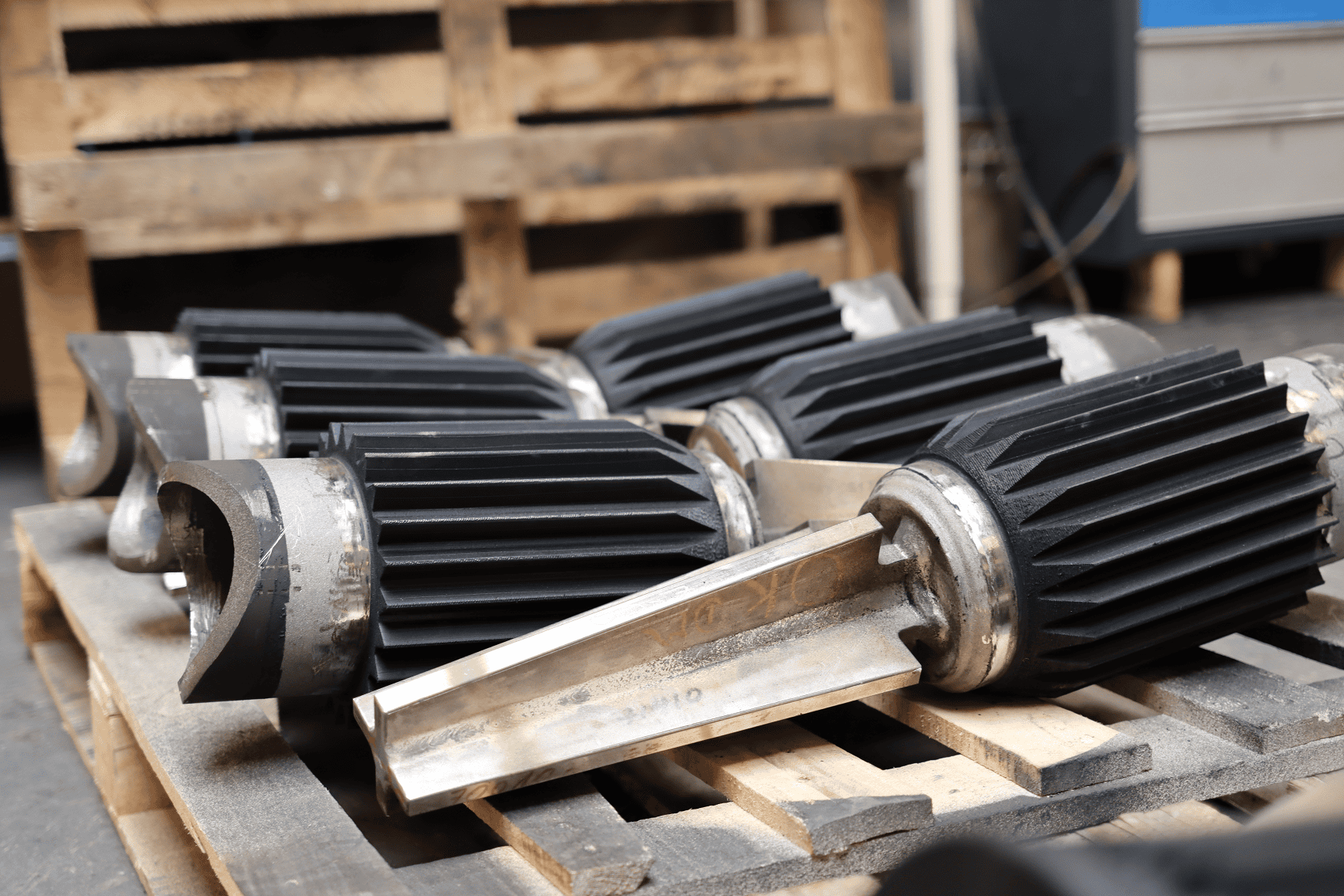

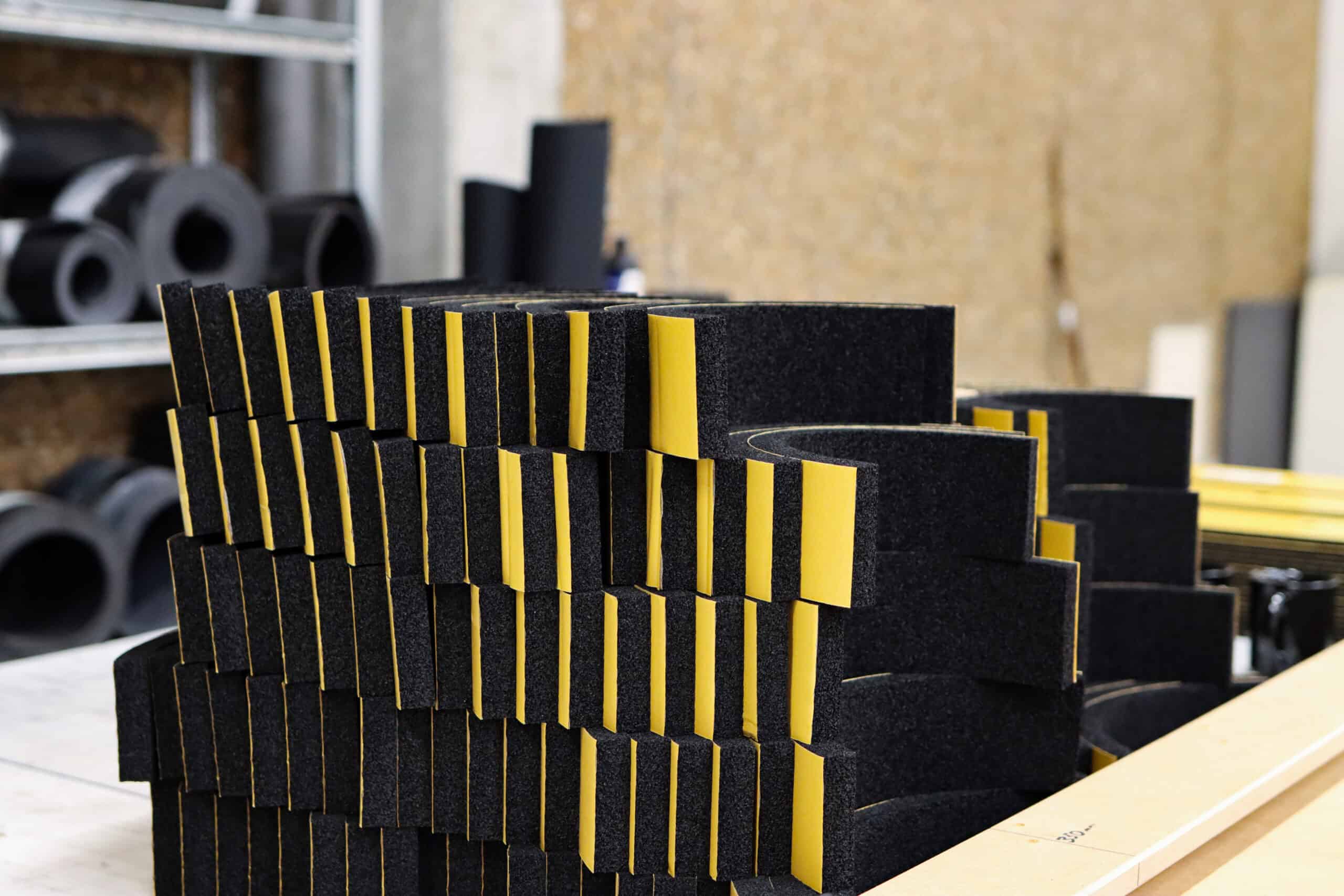

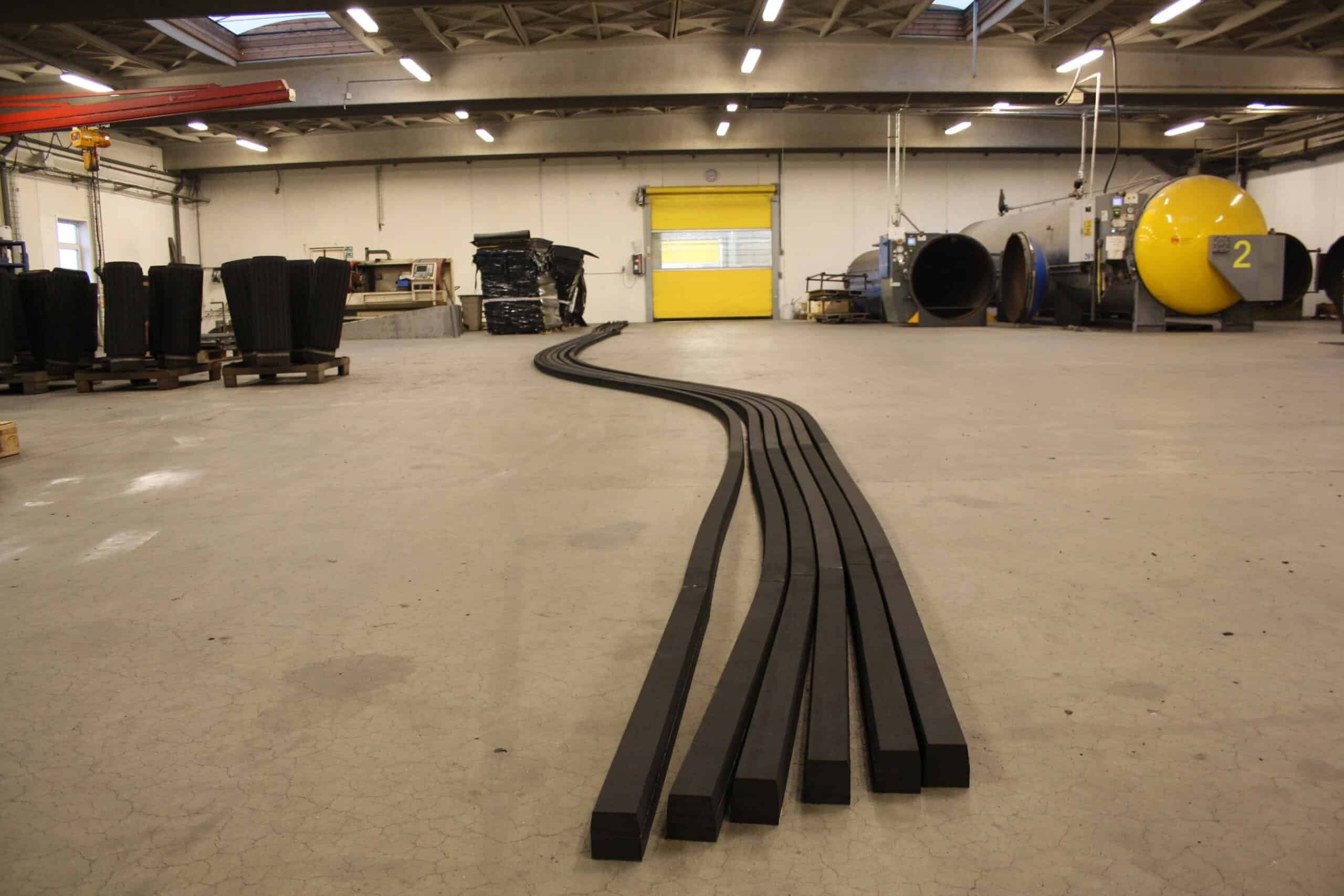

RG ROM GUMMI manufactures and offers an impressively wide range of rubber, plastic and foam solutions and products for the offshore and wind turbine industry. With an impressive track-record of more than 72 wind farms, we specialize in solutions for various parts on foundations, wind turbine towers, and nacelles.

With our innovative thinking, solid craftsmanship and state-of-the-art production facilities, we can offer the best and most advanced solutions, regardless of project size.

EXTENSIVE EXPERTISE. EVEN GREATER TRACK RECORD.

We are proud to be a world-leading manufacturer of custom solutions in rubber, plastic, and foam for wind turbines and offshore wind turbine foundations. Since 2008, we have collectively produced and delivered to more than 70 offshore wind farms.

BEING THE FIRST. KEEPING THE LEAD.

We are proud to be among the world’s leading and most specialized manufacturers of technical solutions in rubber, plastic, and foam for the offshore and wind turbine industries.

For us, it is essential to be a superior manufacturer and collaborative partner, with fast response times, reliable delivery, top-quality products, and clear agreements as our key priorities.

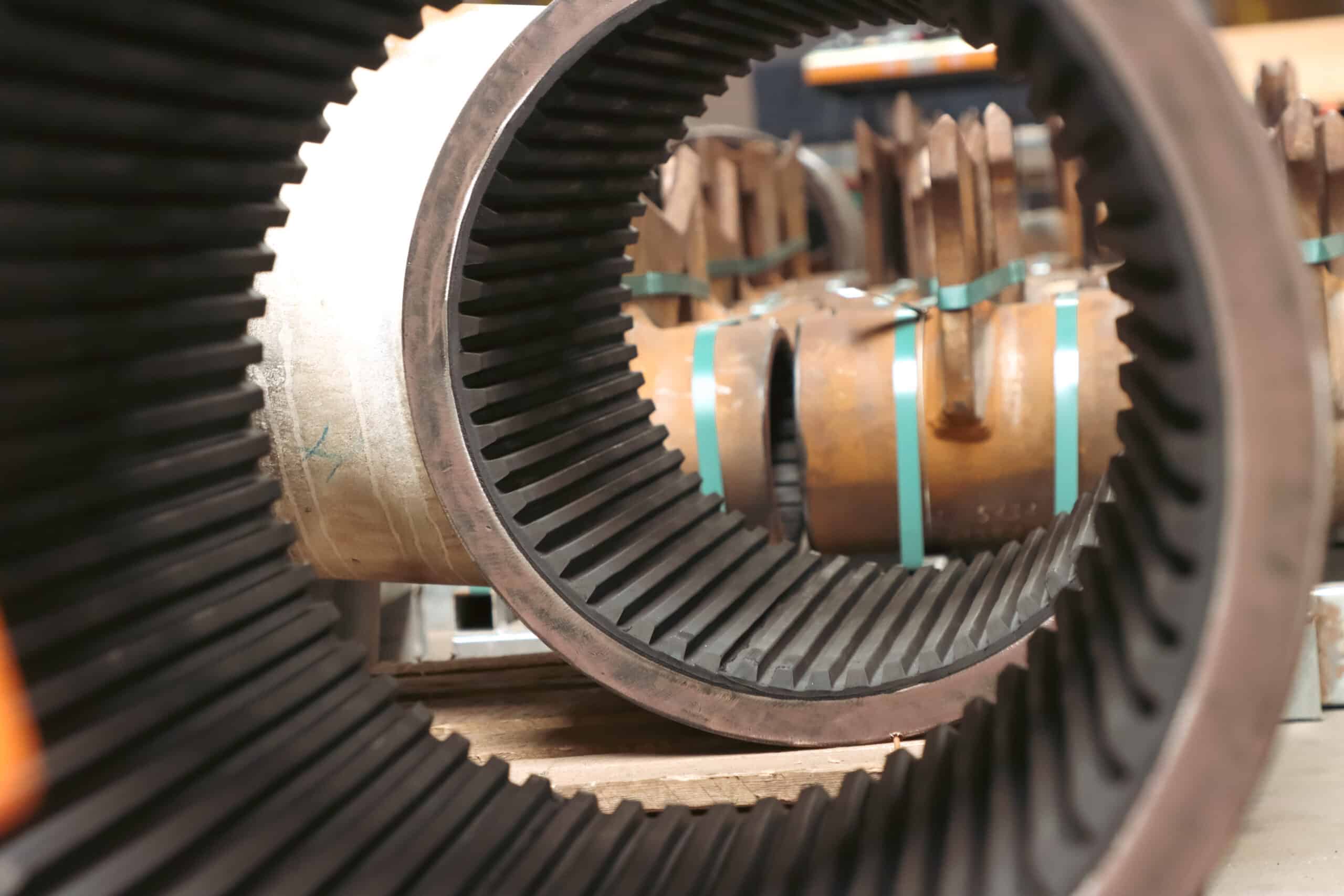

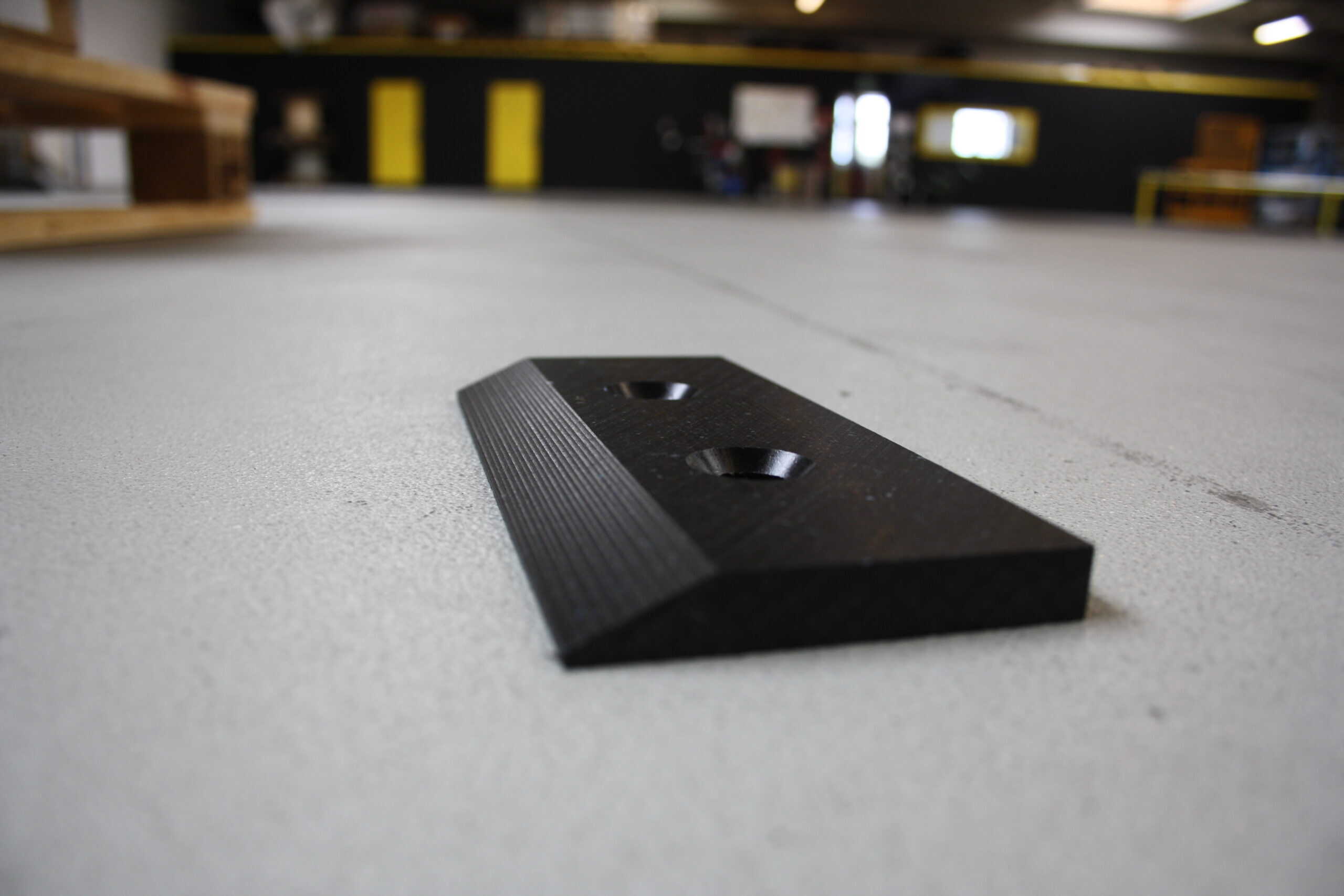

A SPECIAL TYPE OF RUBBER FOR DEMANDING PROJECTS. THATS OUR RG RUBBER.

We know that the demands for durability and wear resistance in technical rubber used for offshore projects are extremely high. That’s why, as a rubber manufacturer, we’ve also developed our very own rubber compounds, RG60, RG Marine Neoprene and RG Neoprene, which is specially designed to withstand the harsh conditions and environment it’s exposed to in offshore wind turbine foundations or wind turbines.

Today, our rubber compounds are recognized by energy companies such as Ørsted and, thanks to their unique properties, are a preferred rubber compound for, for example, boat landings on offshore wind turbine foundations.

DISCOVER THE PERFORMANCE.

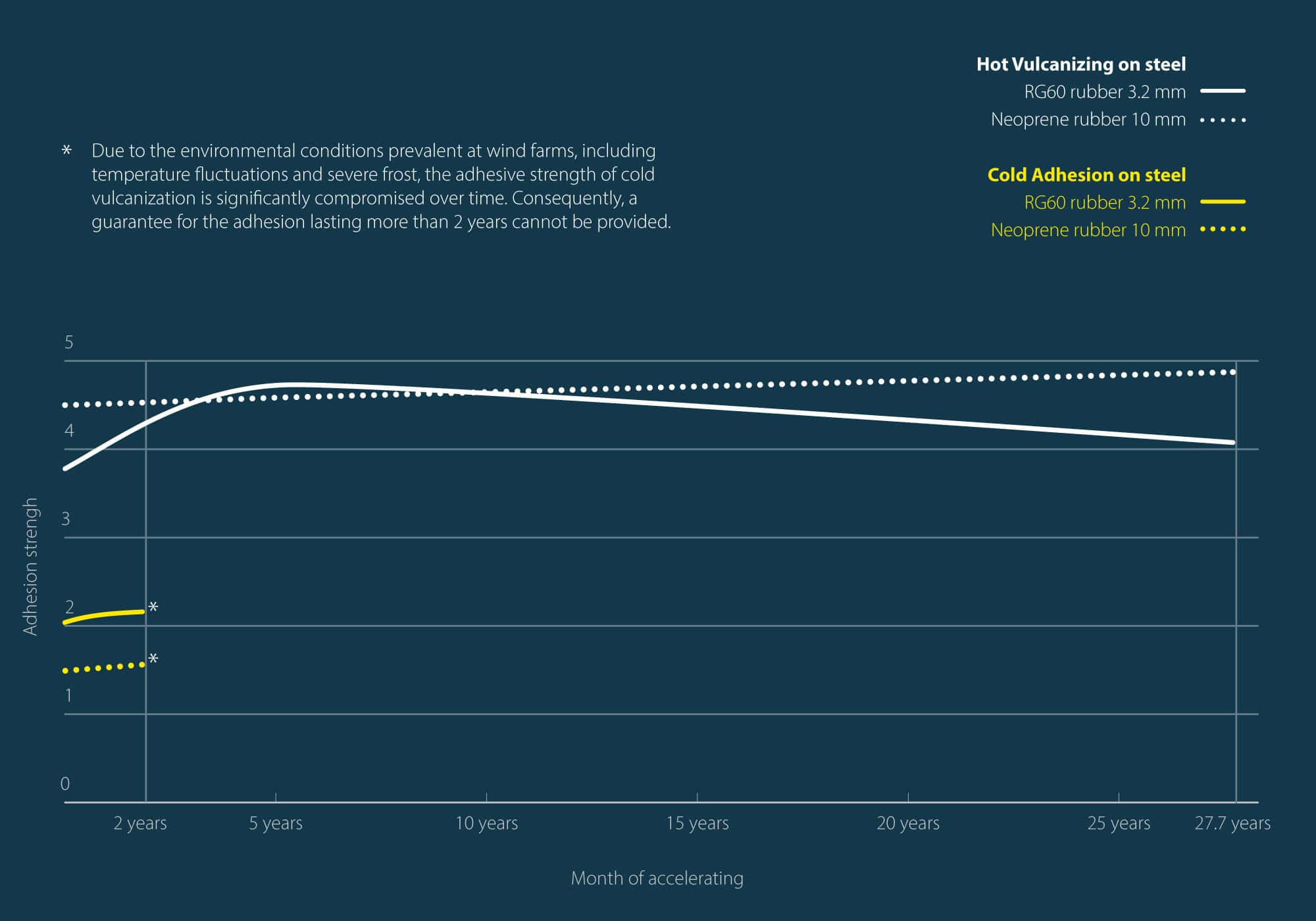

A SIGNIFICANT DIFFERENCE IN ADHESION OVER 27.7 YEARS.

We know that the durability and wear resistance of our hot vulcanized rubber solutions are first class and among the best in the market. To prove that their durability meets the quality requirements of the offshore and wind industry, we have tested their adhesion strength on steel and shown that their lifetime reaches at least 27.7 years.

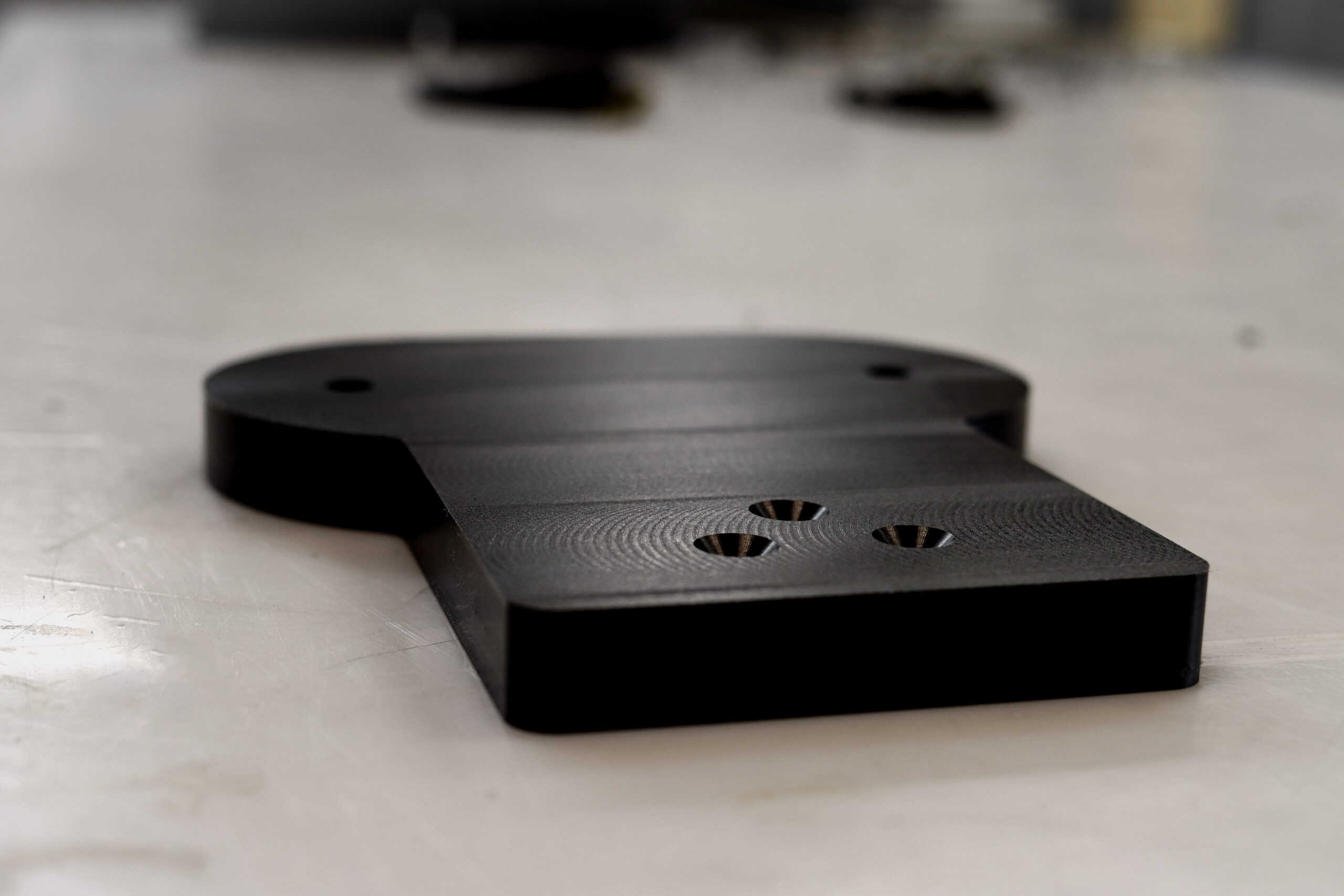

NOT SURE ABOUT THE DESIGN? LET’S TEST IT IN A MOCK-UP.

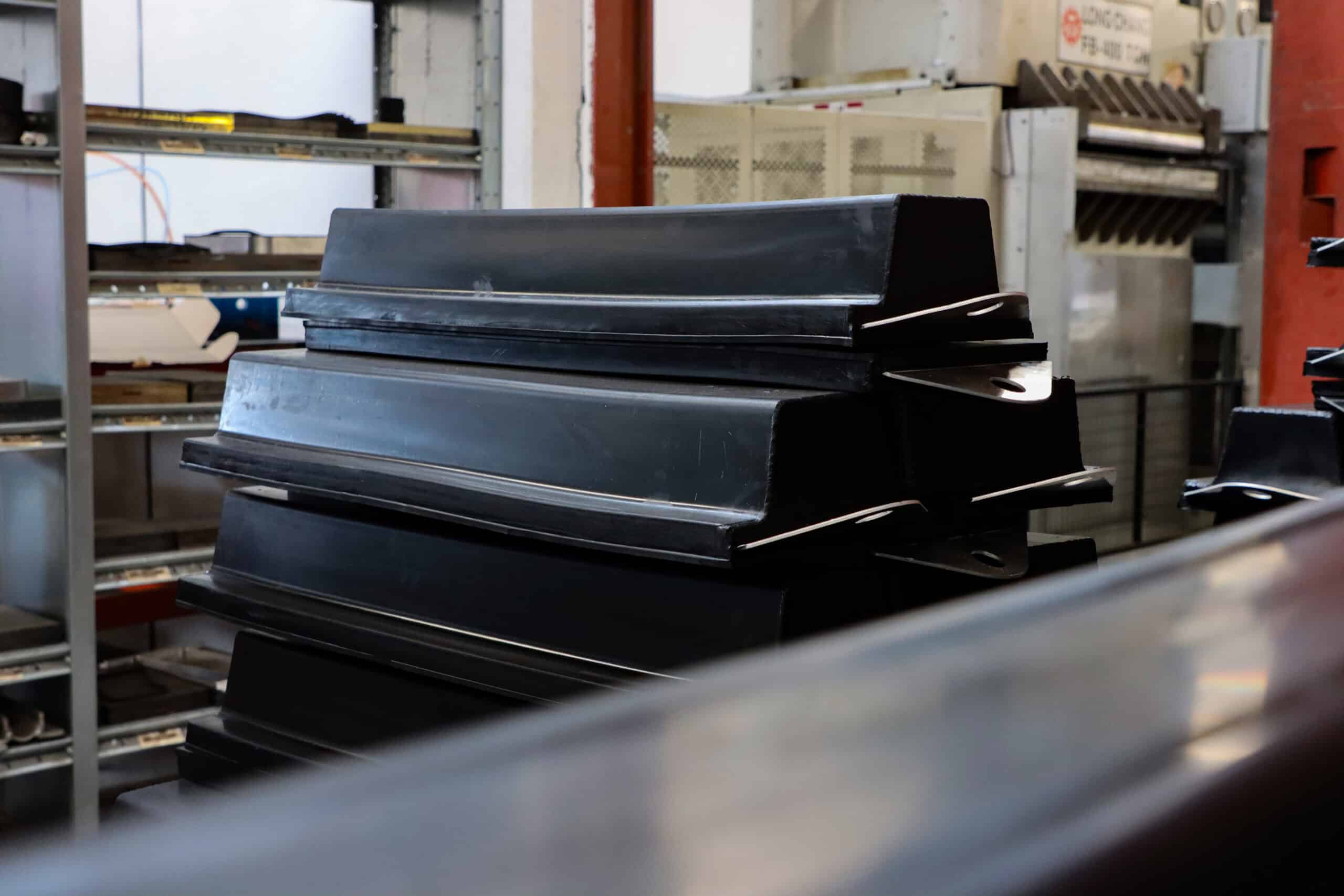

As a designer or engineer of offshore wind turbine foundations, including boat landings, you know that the rubber coating of the boat landing has a major impact on its ability to slide into the transition pieces of the offshore wind turbine foundation during installation.

Uniquely, we can test your design ideas and visualize how the rubber affects a boat landing installation. This allows you to create a final design that is fully optimized before final production begins. The test also provides a real-time view of how the rubber design is affected after installation.

kontakt os.

LET’S DIVE DEEP AND FIND THE PERFECT SOLUTION.

Do you have a challenge or an idea for a solution in rubber, plastic, or foam? Or are you interested in learning more about our solutions and expertise? Don’t hesitate to reach out to one of our specialists. Let’s delve into the details so we can work together to find the perfect solution tailored to your needs.